Application Industries

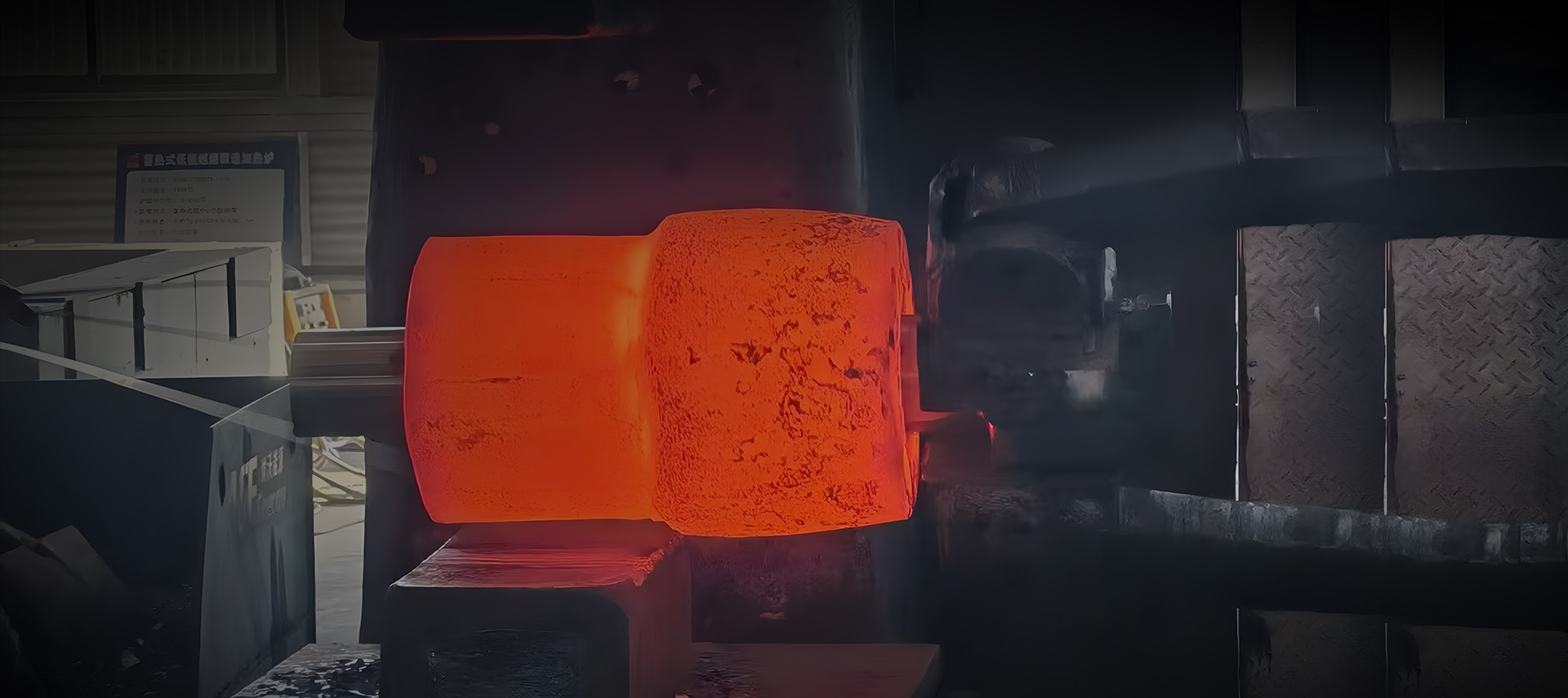

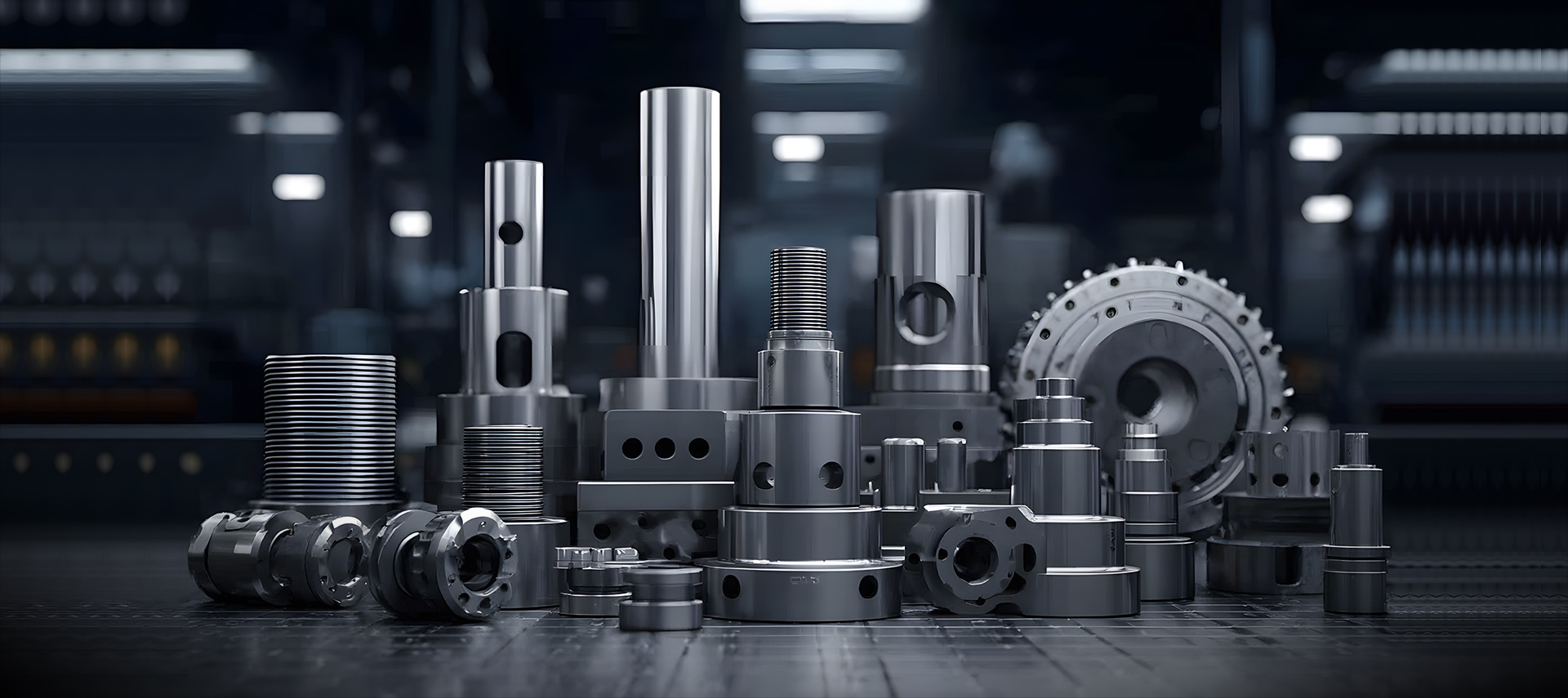

ACE is dedicated to one-stop manufacturing supplier for forging, heat treatment, and machining by lean production.

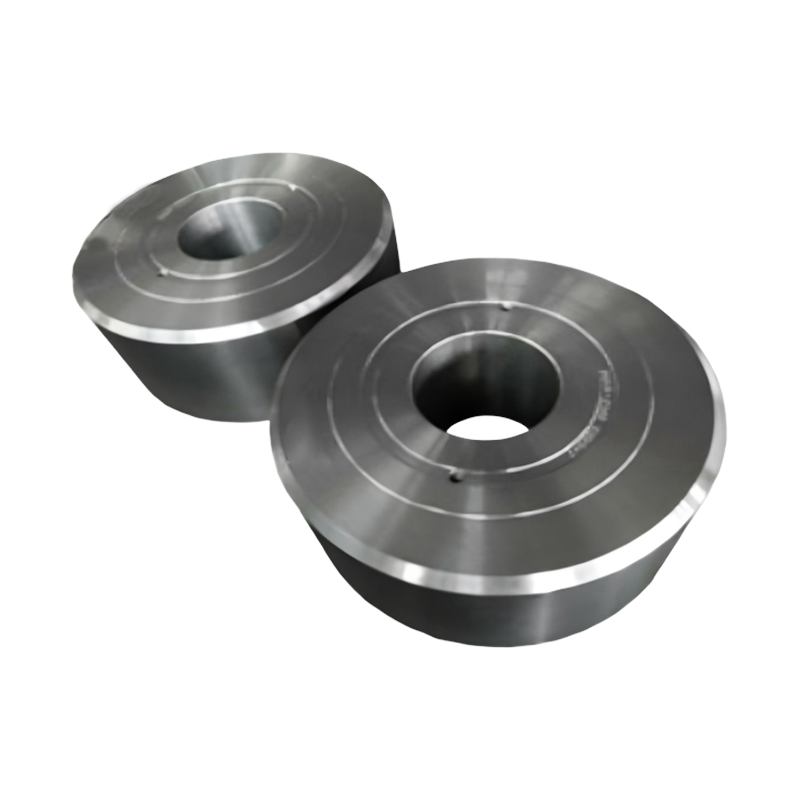

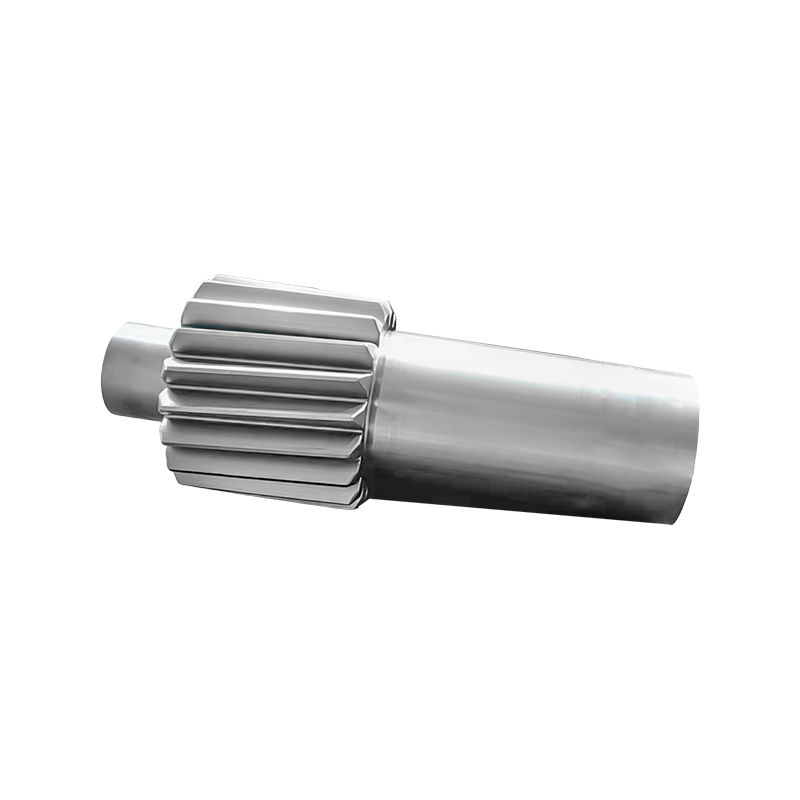

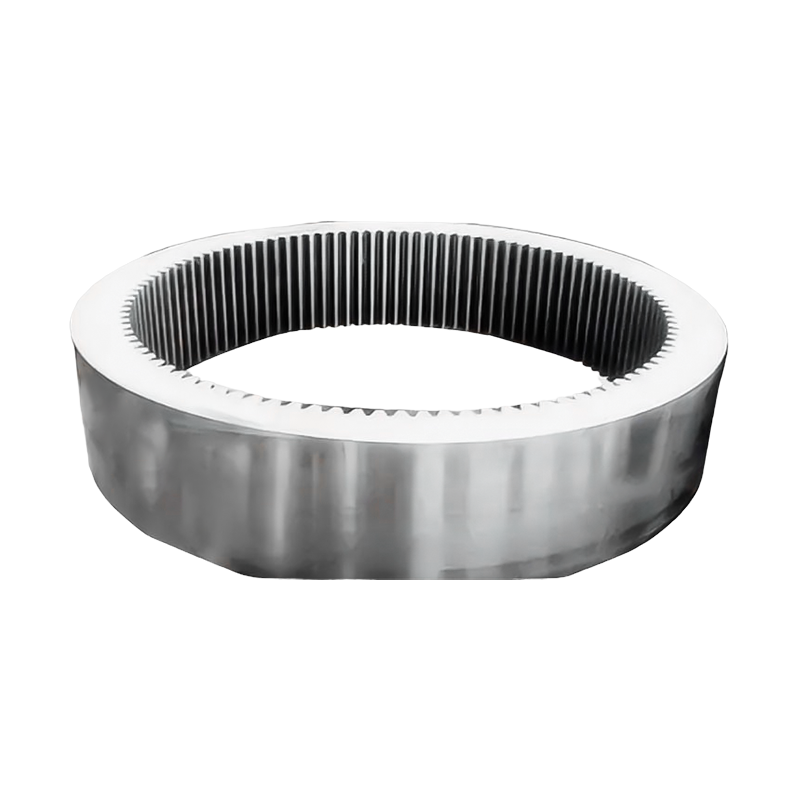

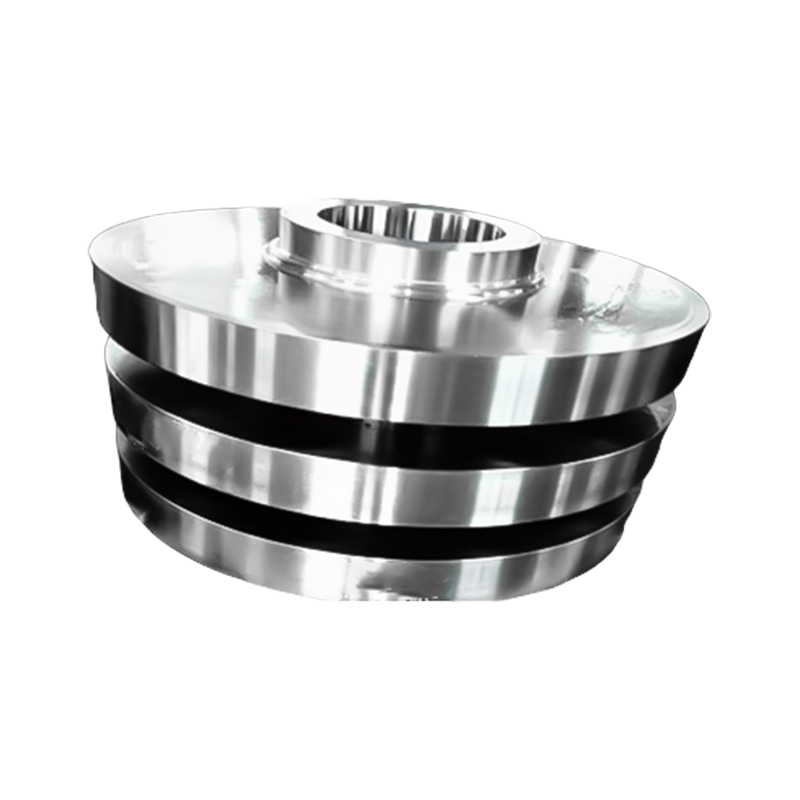

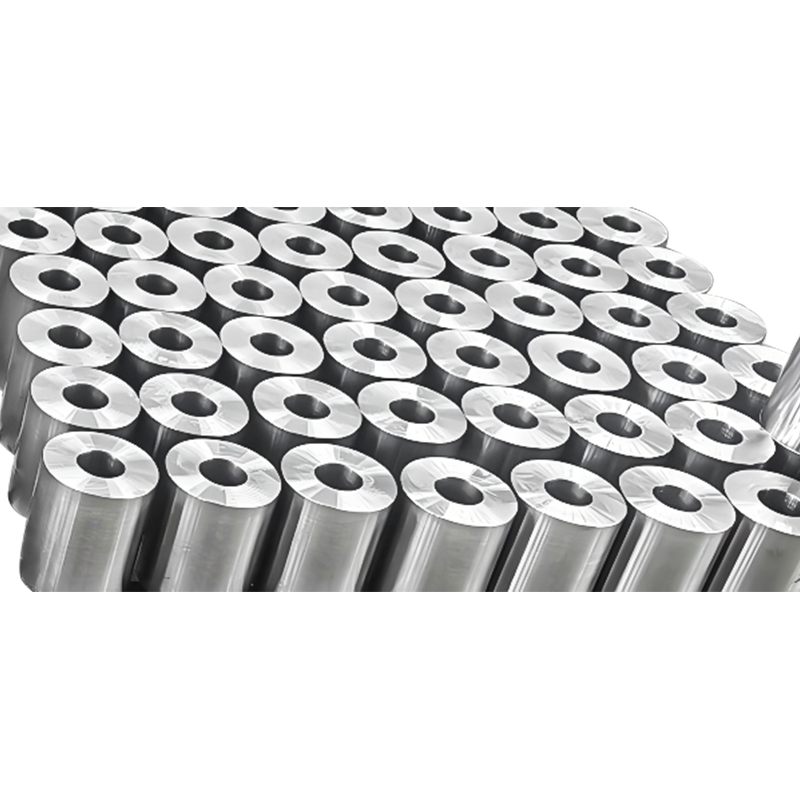

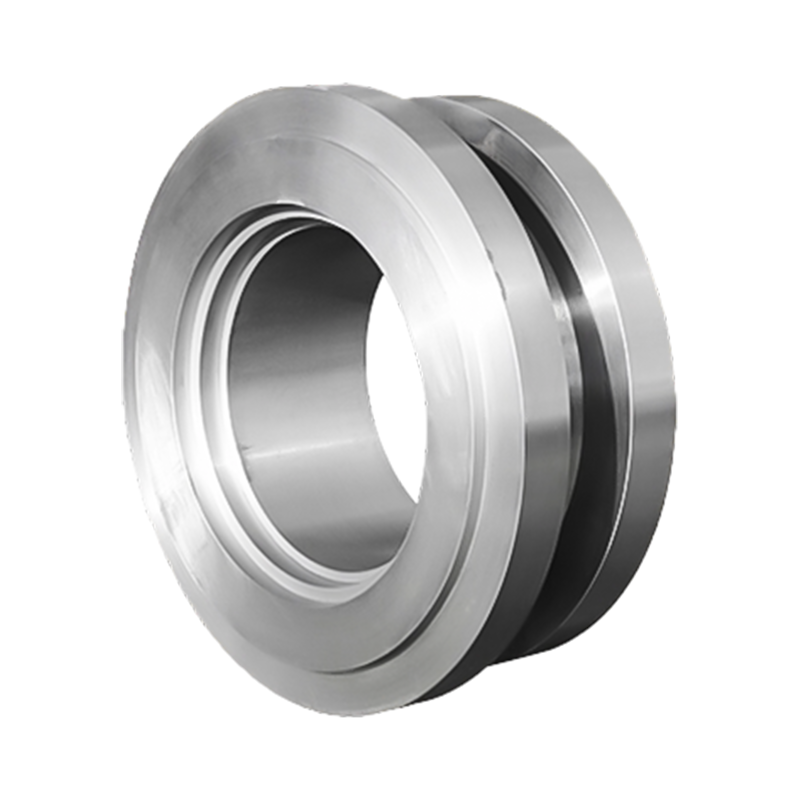

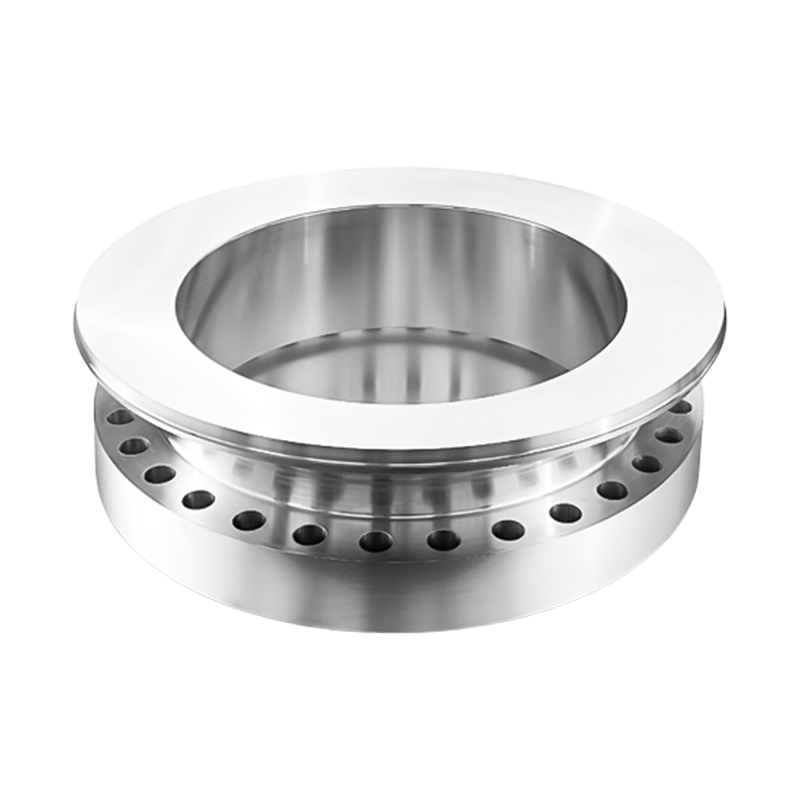

We Specialize in Forgings

Custom & Manufacturing

Yancheng ACE Machinery Co., Ltd.

China open die forgings manufacturer and custom precision forgings supplier

. We specialize in the production and processing of large and complex forgings, and are able to meet a variety of non-standard customization needs, providing systematic solutions for demanding industries.-

0M²

Factory Cover Area

-

0+Millions

Annual Output Value

-

0Tons

Annual Production

-

0+

Engineers

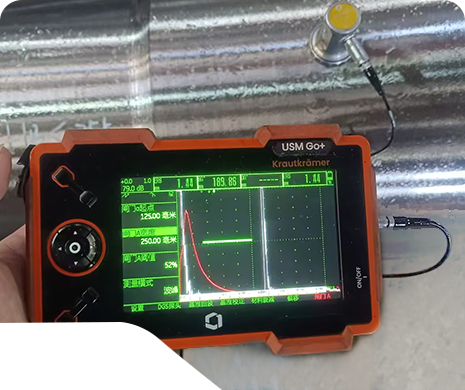

Proven Capabilities

ACE has complete set of test and inspection facilities and expertise, capable of UT, PT, and MPI

with qualified

operators.

-

01

ACE is teamed with highly qualified professional personnel specialized in metal materials, machining, welding, surface treatment, etc. -

02

Heat Treatment

A process of heating and cooling materials, the metals, to alter their physical, mechanical, and chemical properties without changing their shape. -

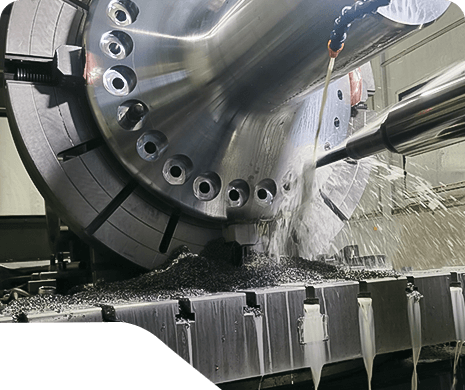

03

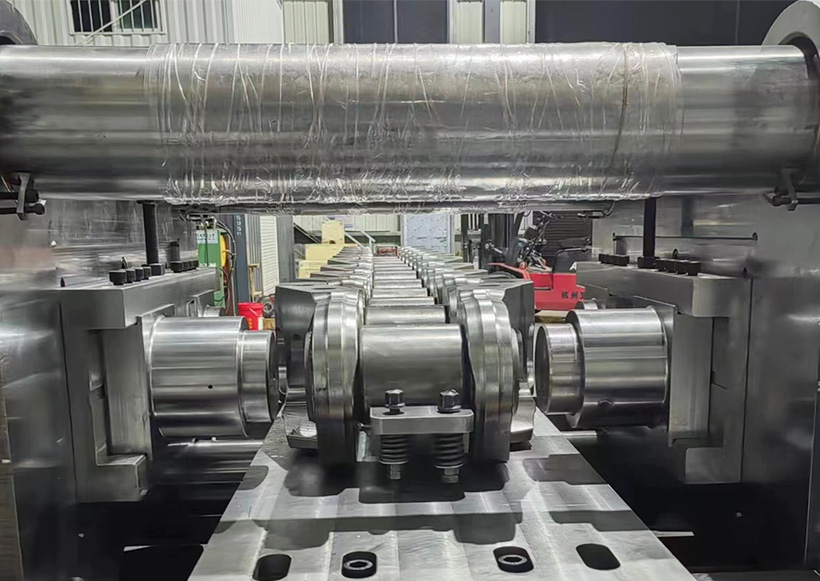

Precision Machining

A manufacturing process that uses computer-controlled machines to cut and shape metal into parts with extremely high accuracy and tight tolerances. -

04

Quality Inspection

It is a quality control process that involves evaluating metal products at various stages to ensure they meet specifications and standards.

Successful Projects

Diversity offers flexibility, capability offers reliability, ACE Machinery aims to be one-stop

ace solution

provider for our customers.

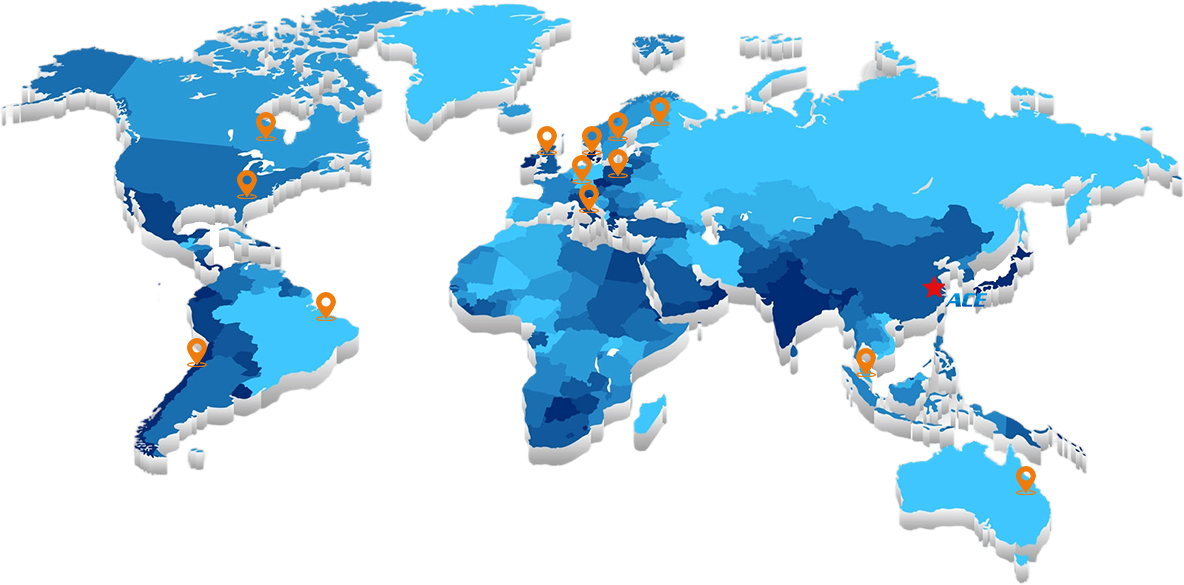

Global Partners

With excellent quality and craftsmanship, over 95% of our products are exported to countries and regions including

the Netherland, Germany, Sweden, Denmark, Finland, Italy, the United Kingdom,

Canada, America, Chile, Brazil, Singapore, Austrilia, and so on.

News Update

Follow company news and stay informed about industry trends

English

English 中文简体

中文简体