Annealing: Heating metal to specific temperature and then slowly cooling it.

Normalizing: This process improves the uniformity of the grain structure and mechanical properties.

Quenching: Heating metal to a critical temperature and then rapidly cooling it by immersing it in quenching medium.

Tempering: This process, performed after quenching, reheats the metal to a lower temperature.

Induction Hardening: Hardening increases the surface hardness and anti-wear properties of material.

-

Wind Turbine 5MW-10MW 1st/2nd/3rd Stage Planet Gear Forgings

-

Wind Turbine 5MW-10MW 1st/2nd/3rd Stage Sun Gear Forgings

-

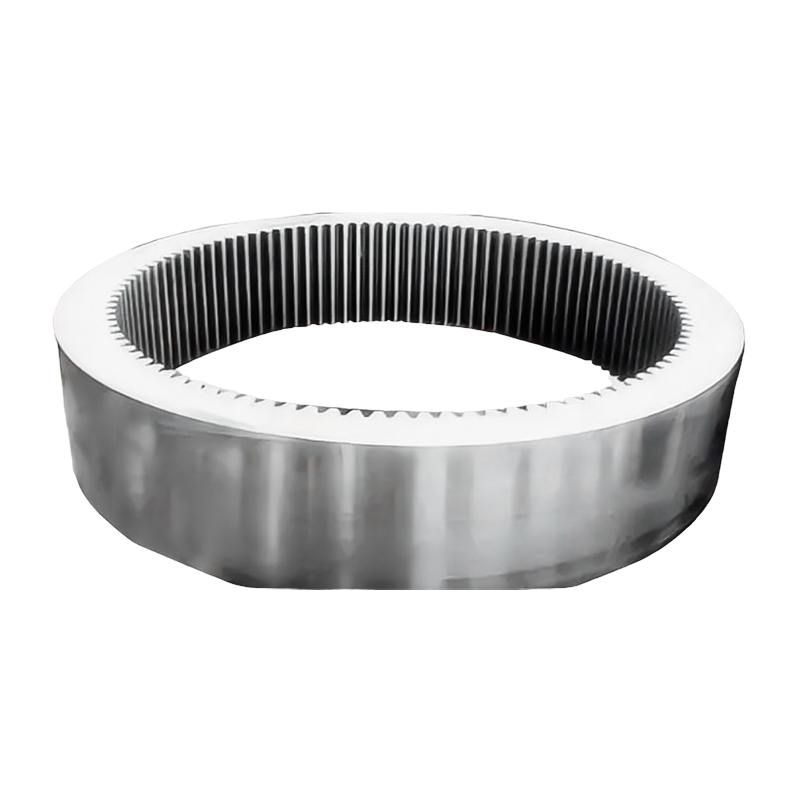

Wind Turbine 5MW-10MW 1st/2nd Stage Ring Gear Forgings

-

Wind Turbine 3MW-10MW Planet Carrier Forgings

-

Hydroelectric Generator Shaft Forgings

-

Nuclear Power Conventional Island Parts Forgings

-

Tube Sheet Forgings

-

Marine Rudder Pintle Forgings

English

English 中文简体

中文简体