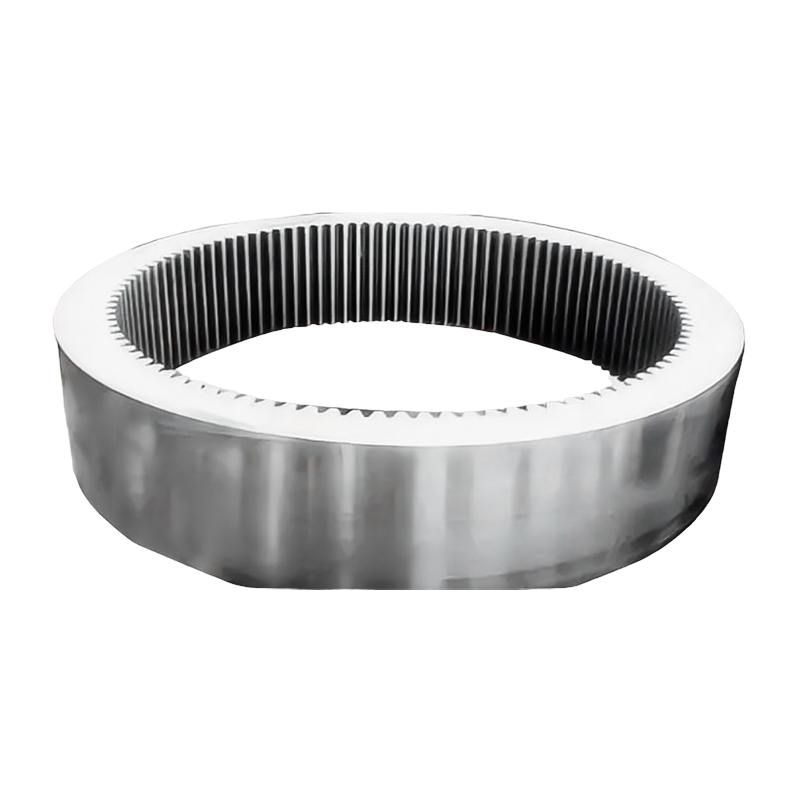

ACE Group is a comprehensive enterprise group focused on the heavy industrial manufacturing sector, serving as a China Wind Turbine 5MW-10MW 1st/2nd/3rd Stage Planet Gear Forgings Manufacturers and Wholesale Wind Turbine 5MW-10MW 1st/2nd/3rd Stage Planet Gear Forgings Factory. Its business spans forging, heat treatment, precision machining, welded structures, and heavy-duty power & free chain spraying production. This integrated layout covers the core production processes of the industrial machinery industry, combining technological strength with large-scale production capabilities.

Core Subsidiaries Details:

Jiangsu ACE Energy Technology Co., Ltd.: The group's core production base, officially commencing operations in November 2025. It occupies 55 acres with a total floor area exceeding 50,018 square meters. The factory is equipped with 3-ton, 5-ton, and 15-ton electro-hydraulic hammers; 1-meter and 1.5-meter vertical ring rolling machines; energy-efficient natural gas heating furnaces; heat treatment resistance furnaces; quenching tanks; induction hardening equipment; machining centers; and other production equipment.

Yancheng ACE Machinery Co., Ltd.: Established in 2019, it occupies 20 acres with a floor area of 13,333 square meters. It possesses an integrated welding-straightening structural steel production line and a precision machining workshop.

Yancheng ACE Surface Treatment Technology Co., Ltd.: Operates a heavy-duty power & free chain large-scale powder coating production line. Focusing on professional surface treatment technology, One-time coating thickness achieves 400μm, providing reliable anti-corrosion and weather-resistant protective performance and appearance optimization solutions, enhancing the group's full life-cycle product services.

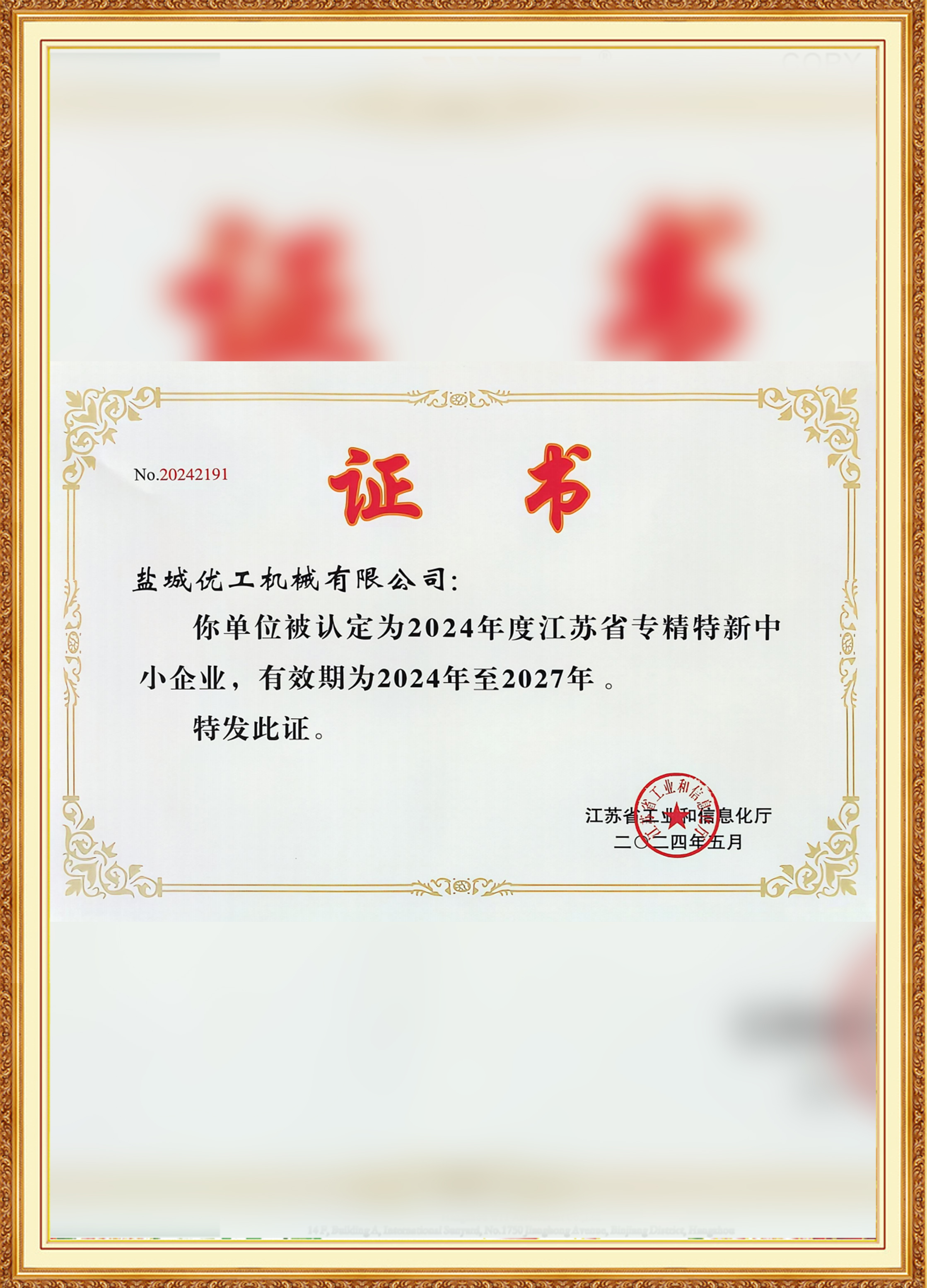

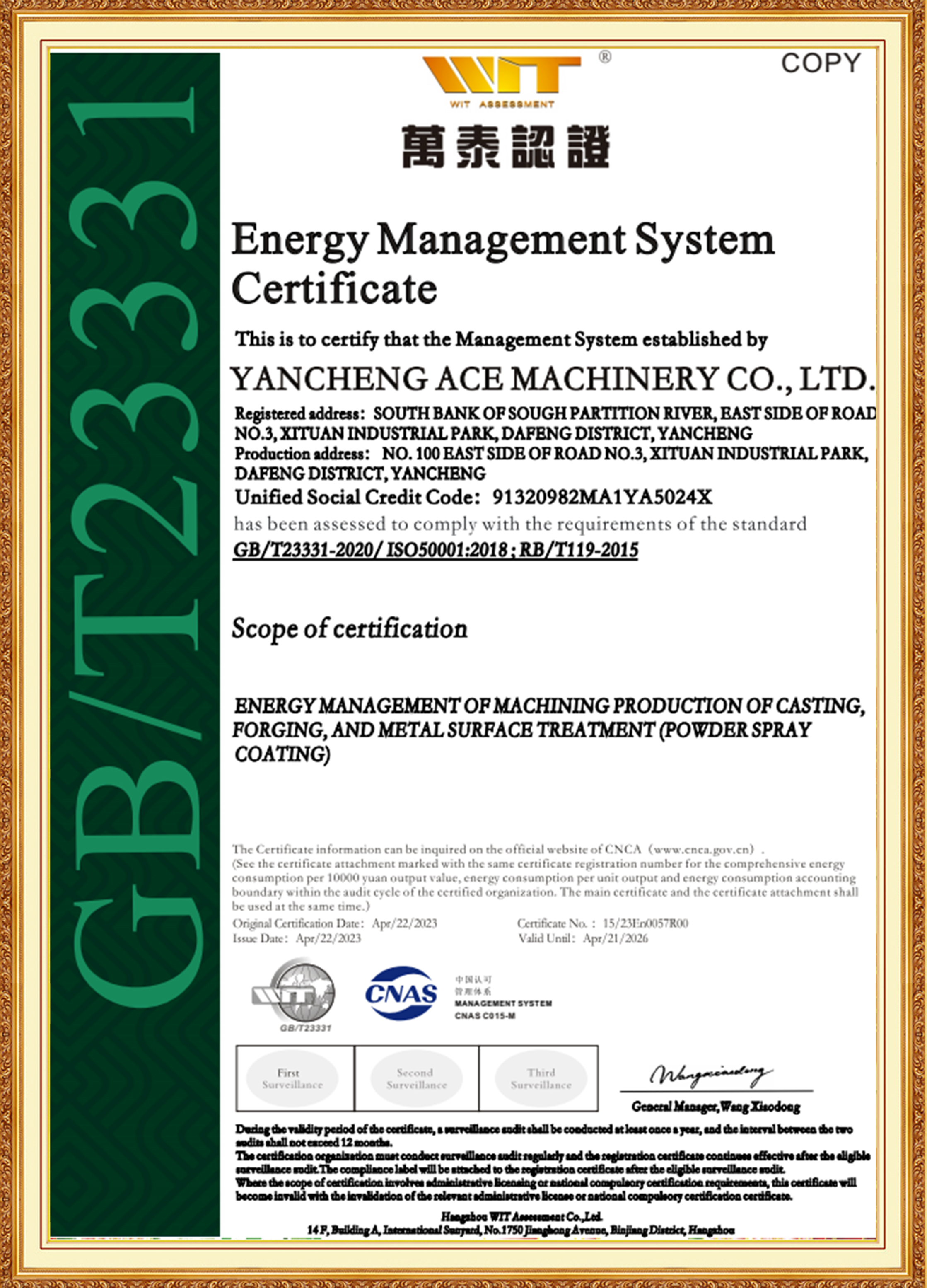

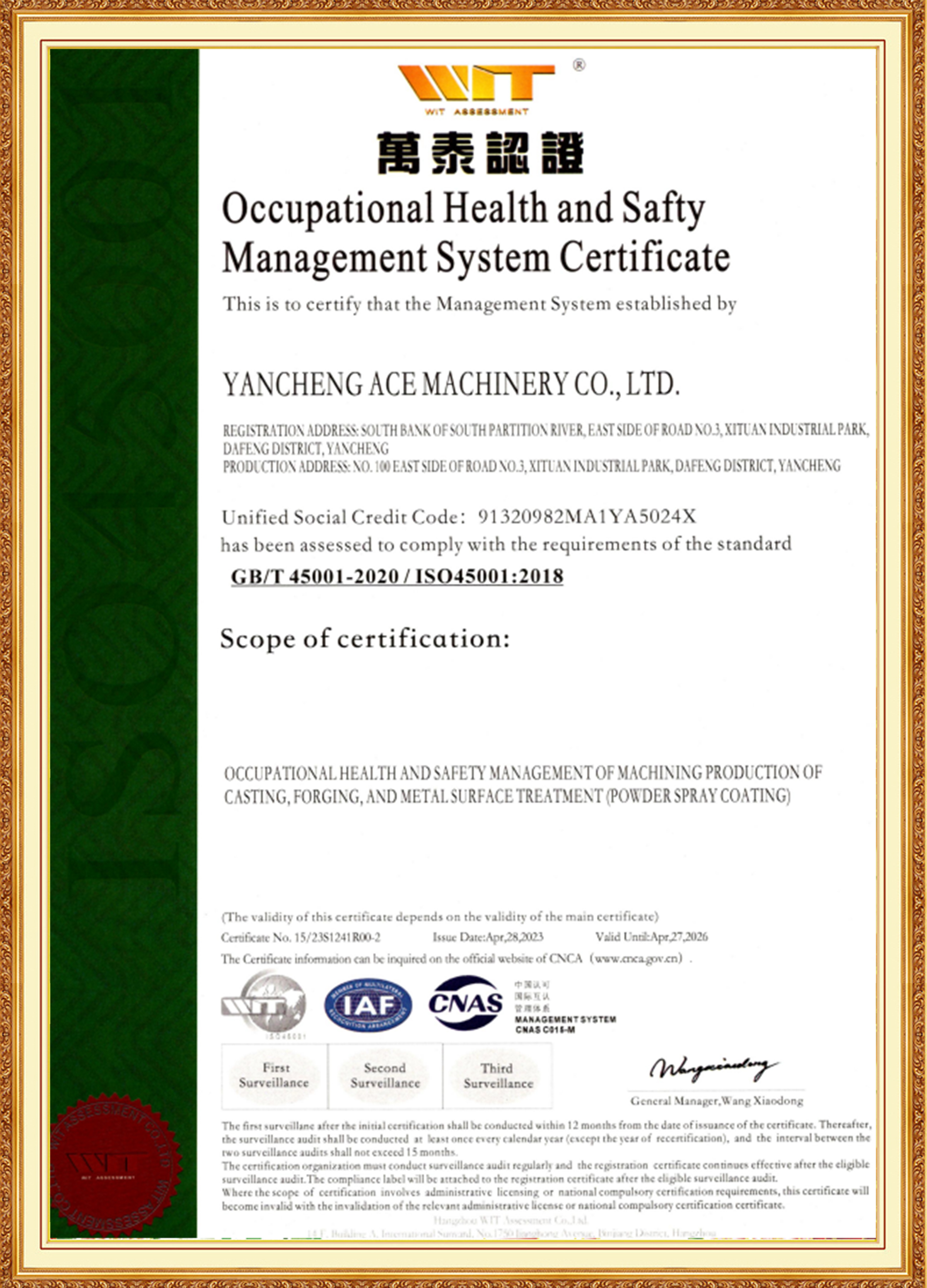

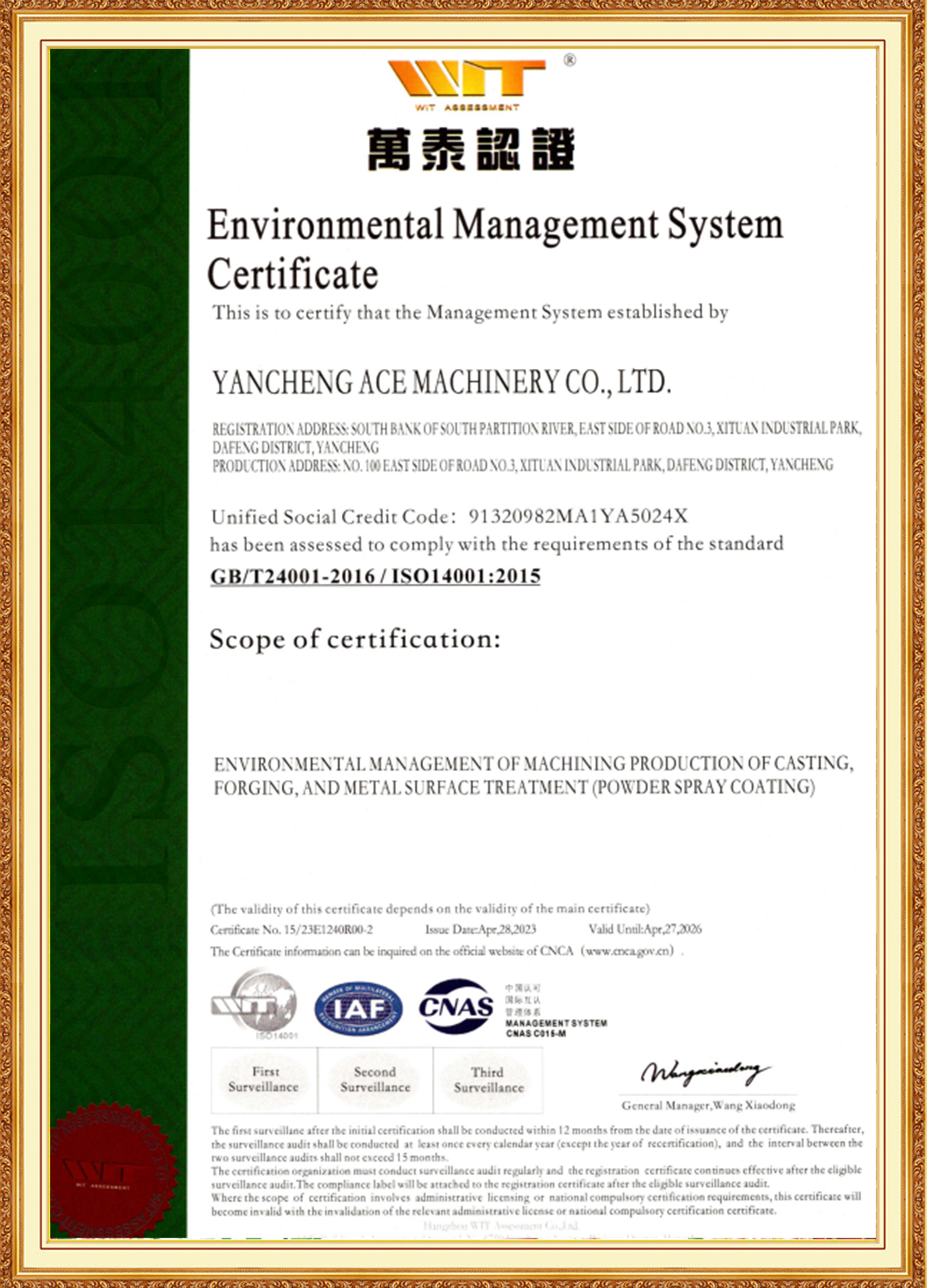

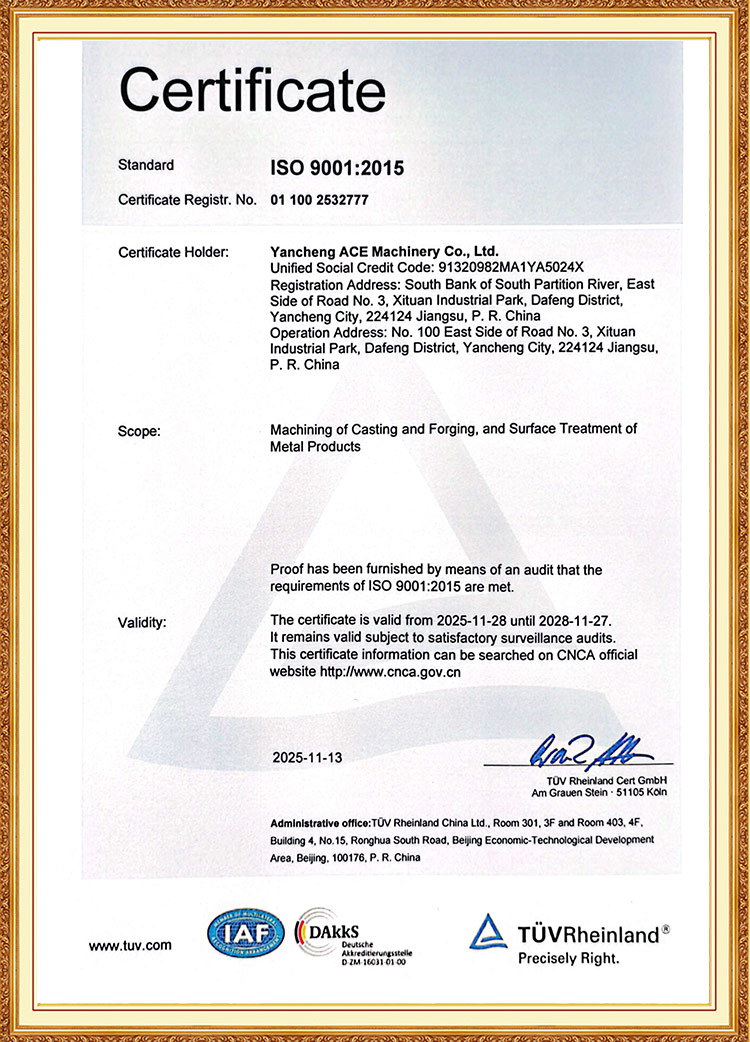

ACE Group is supported by a management team of young key members who are experienced in materials, heat treatment, machining, and surface treatment industries. They are well-versed in international and domestic standards, pioneering, and committed to innovation. The subsidiary ACE Machinery has passed TÜV Rheinland ISO 9001 Quality Management System certification, as well as ISO 14001, 45001, and 50001 system certifications. It is recognised as a Specialised, Refined, Unique, and Innovative Enterprise, a National High-Tech Enterprise, and holds a 3A-level enterprise credit rating.

Relying on integrated MES and ERP management systems, the integration of informatisation and industrialisation, data cloud storage, and aiming to build a modern, energy-efficient enterprise, the group maintains a comprehensive inspection system. It possesses inspection tools, non-destructive testing equipment, and qualified personnel, implementing strict controls from material internal quality to appearance and dimensions. All outgoing products undergo 100% inspection, adhering to the business philosophy of pursuing 100% qualified outgoing products and zero customer complaints. A CNAS-standard laboratory will be established to provide scientific testing support for quality control during production and technological R&D, thereby enhancing product quality and technological innovation.

In the future, ACE Group will continue to leverage the technical advantages and industrial synergies of its subsidiaries. Through standardised production, specialised technology, integrated services, and a stringent quality control system, it is committed to providing efficient and reliable industrial manufacturing solutions for global clients, steadily advancing towards becoming a leading comprehensive manufacturing service provider in the industry.

English

English 中文简体

中文简体