Gear Forgings Supplier

Applications

As core transmission parts for pellet mills and mixers, they fit different machine models, ensuring accurate and efficient raw material processing.

Production

Wear-resistant, compliant stainless steel (e.g., 304, 316L) is selected. Through forging, precision machining, sanitary polishing (Ra ≤ 0.8 μm), and non-destructive testing, they meet food and feed safety standards.

Services

Custom design and after-sales maintenance guidance are provided.

Advantages

With high strength and wear resistance, they withstand high-frequency operations, reduce downtime, and support efficient, compliant production in the industry.

About Us

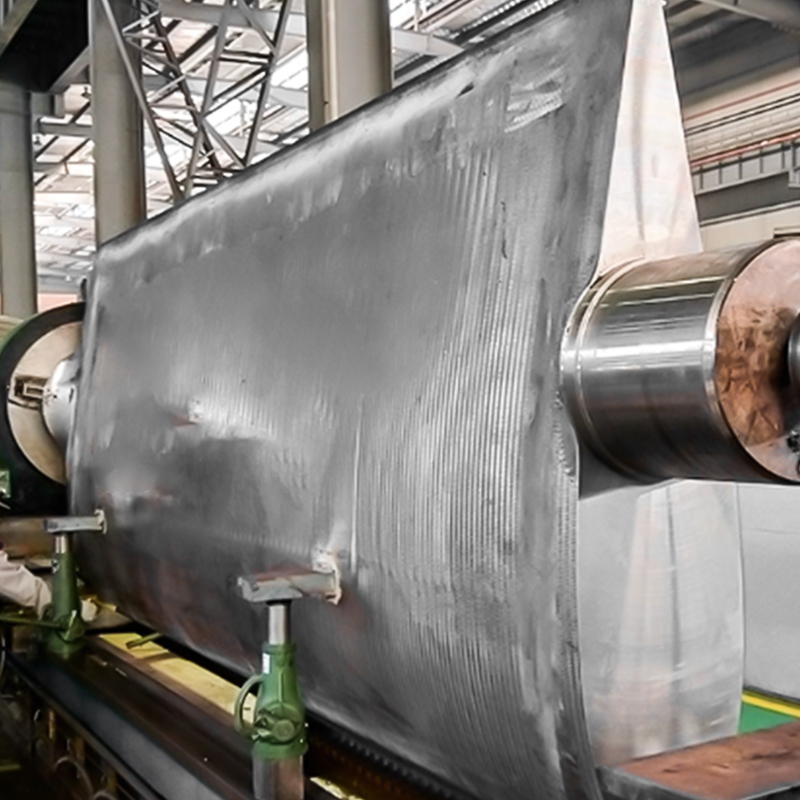

ACE Group is a comprehensive enterprise group focused on the heavy industrial manufacturing sector, serving as a China Gear Forgings Supplier and Ring Forgings Company. Its business spans forging, heat treatment, precision machining, welded structures, and heavy-duty power & free chain spraying production. This integrated layout covers the core production processes of the industrial machinery industry, combining technological strength with large-scale production capabilities.

Core Subsidiaries Details:

Jiangsu ACE Energy Technology Co., Ltd.: The group's core production base, officially commencing operations in November 2025. It occupies 55 acres with a total floor area exceeding 50,018 square meters. The factory is equipped with 3-ton, 5-ton, and 15-ton electro-hydraulic hammers; 1-meter and 1.5-meter vertical ring rolling machines; energy-efficient natural gas heating furnaces; heat treatment resistance furnaces; quenching tanks; induction hardening equipment; machining centers; and other production equipment.

Yancheng ACE Machinery Co., Ltd.: Established in 2019, it occupies 20 acres with a floor area of 13,333 square meters. It possesses an integrated welding-straightening structural steel production line and a precision machining workshop.

Yancheng ACE Surface Treatment Technology Co., Ltd.: Operates a heavy-duty power & free chain large-scale powder coating production line. Focusing on professional surface treatment technology, One-time coating thickness achieves 400μm, providing reliable anti-corrosion and weather-resistant protective performance and appearance optimization solutions, enhancing the group's full life-cycle product services.

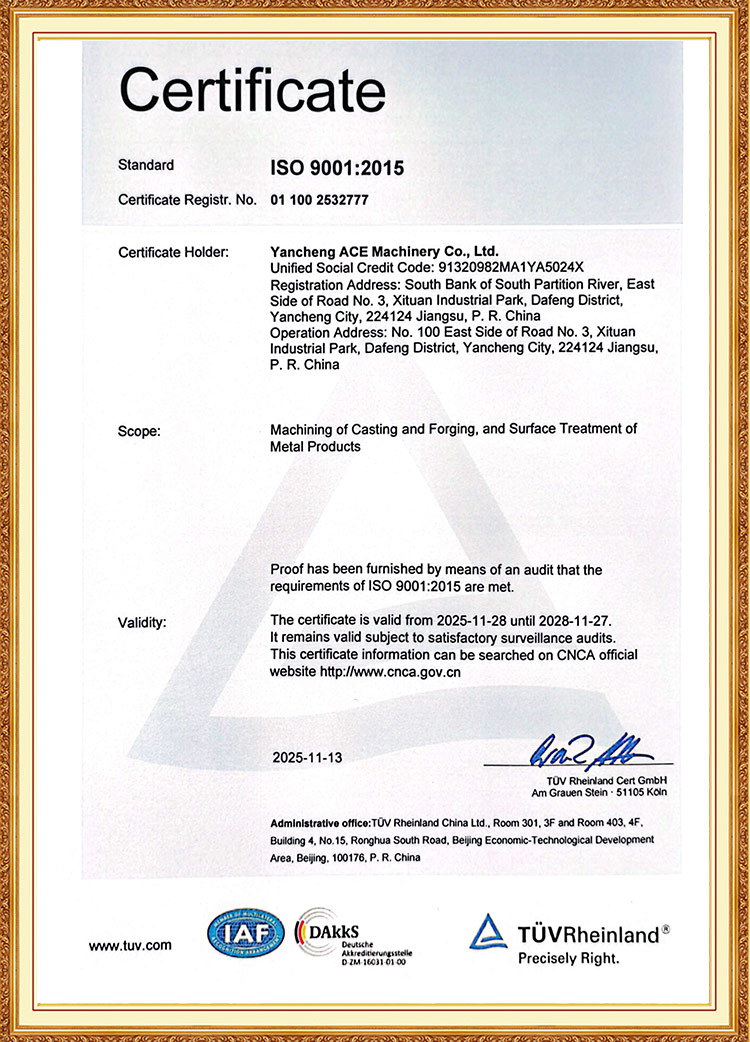

ACE Group is supported by a management team of young key members who are experienced in materials, heat treatment, machining, and surface treatment industries. They are well-versed in international and domestic standards, pioneering, and committed to innovation. The subsidiary ACE Machinery has passed TÜV Rheinland ISO 9001 Quality Management System certification, as well as ISO 14001, 45001, and 50001 system certifications. It is recognised as a Specialised, Refined, Unique, and Innovative Enterprise, a National High-Tech Enterprise, and holds a 3A-level enterprise credit rating.

Relying on integrated MES and ERP management systems, the integration of informatisation and industrialisation, data cloud storage, and aiming to build a modern, energy-efficient enterprise, the group maintains a comprehensive inspection system. It possesses inspection tools, non-destructive testing equipment, and qualified personnel, implementing strict controls from material internal quality to appearance and dimensions. All outgoing products undergo 100% inspection, adhering to the business philosophy of pursuing 100% qualified outgoing products and zero customer complaints. A CNAS-standard laboratory will be established to provide scientific testing support for quality control during production and technological R&D, thereby enhancing product quality and technological innovation.

In the future, ACE Group will continue to leverage the technical advantages and industrial synergies of its subsidiaries. Through standardised production, specialised technology, integrated services, and a stringent quality control system, it is committed to providing efficient and reliable industrial manufacturing solutions for global clients, steadily advancing towards becoming a leading comprehensive manufacturing service provider in the industry.

Certificate

-

Enterprise Credit Evaluation AAA

-

2024 Specialized, Refined, Distinctive, and Innovative Enterprise Certificate

-

2023 High-Tech Enterprise Certificate

-

ISO50001 Energy Management System

-

ISO 45001 Occupational Health and Safety Management System

-

ISO 14001 Environmental Management System

-

ISO 9001 Quality Management System

News

-

Company News 2026-01-25

After 6 months of precision engineering and collaboration, we are proud to announce the completion of our 700m rail supply for the Berendrechtsluis Lock renovation project at the Port of Antwerp-Bruges, Europe's largest integrated port. The final container, carrying 15 pieces of our 34CrNiMo6 QT T-type heavy-duty T-typ...

View More -

News 2026-01-19

On January 17, 2026, the inaugural annual gala of Jiangsu ACE Energy Technology Co., Ltd. was triumphantly held in an atmosphere brimming with enthusiasm. Over 160 attendees, including distinguished guests from various sectors, partners, government representatives, as well as the company's employees and their families,...

View More -

Company News 2025-11-12

With a resounding clang of the hammer, a new journey begins! Recently, the grand opening ceremony of Jiangsu ACE Energy Co., Ltd.'s forging base and the launch ceremony for the "first hammer" production were held in the Dafeng Economic Development Zone Industrial Park, Jiangsu Province. As ACE Energy Chairman Zhai Liuy...

View More

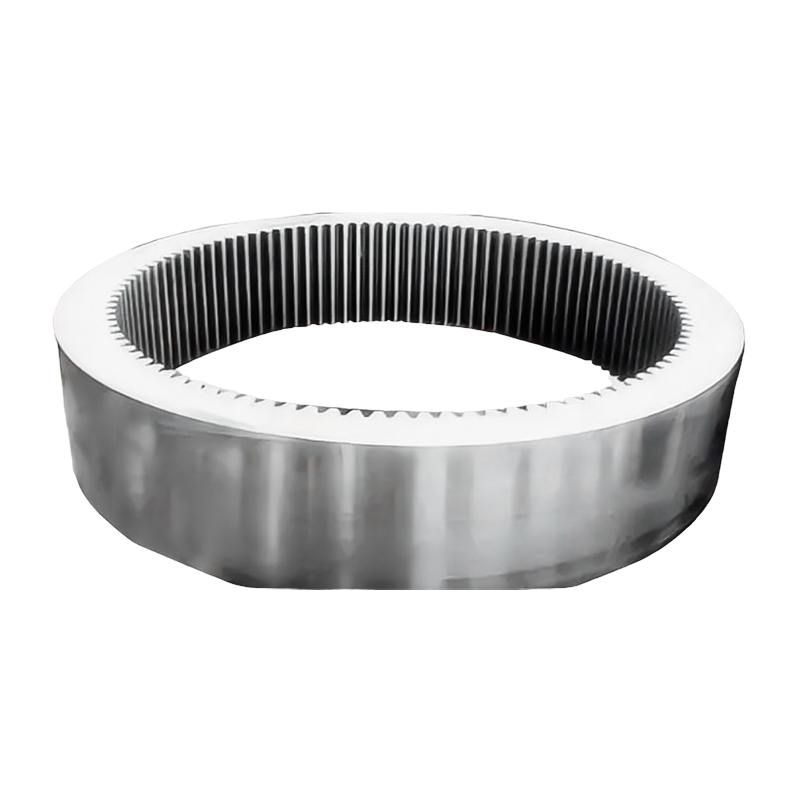

Gear-ring forgings KNOWLEDGE

In the high-intensity world of food and feed manufacturing, the efficiency of a pellet mill or a mixer is entirely dependent on its transmission accuracy. These machines operate under high-frequency load cycles where even the slightest mechanical slip or surface degradation can compromise raw material processing and lead to batch non-compliance. To ensure stable, high-torque performance while meeting rigorous hygiene standards, the industry relies on gear-ring forgings as the gold standard for power transmission.

At ACE Group, we leverage our integrated "Forging-Machining-Polishing" layout to produce transmission components that balance heavy-duty strength with sanitary excellence. Utilizing our specialized vertical ring rolling machines at Jiangsu ACE Energy Technology, we deliver forged rings that define reliability in modern food and feed machinery.

1. Structural Integrity: The Advantage of Seamless Ring Rolling

A transmission ring is only as strong as its weakest point. Unlike "welded-plate" rings or "cast" rings, ACE Group gear-ring forgings are produced through seamless ring rolling. This process expands the metal diameter while compressing the grain structure into a continuous, circular flow.

Why Seamless Forging is Essential:

-

Uniform Load Distribution: The continuous grain flow ensures that transmission forces are distributed evenly across every tooth, preventing localized fatigue.

-

Superior Wear Resistance: Forging eliminates internal porosity, ensuring that once the teeth are machined, the metal remains dense and resistant to the abrasive nature of raw feed materials.

-

Dynamic Stability: Our seamless rings maintain perfect circularity under thermal expansion, reducing vibration and noise during high-speed mixing.

| Performance Metric | ACE Group Forged Gear-Rings | Standard Cast/Welded Rings |

| Microstructure | Seamless, refined grain flow | Prone to weld-line weakness/pores |

| Sanitary Profile | Polished (Ra ≤ 0.8 μm) | Rougher surface (Bacteria traps) |

| Material Integrity | High-density forged stainless | Risk of internal inclusions |

| Operational Life | Extended 40% (Fatigue resistant) | Standard |

2. Sanitary Excellence: Ra ≤ 0.8 μm Polishing

In food-grade applications, the surface finish is a safety requirement. After the precision machining phase at Yancheng ACE Machinery, our gear-ring forgings undergo a specialized sanitary polishing process.

-

Surface Finish: We achieve a roughness of Ra ≤ 0.8 μm, creating a "mirror-like" finish.

-

Safety Benefit: This ultra-smooth surface prevents the adhesion of organic materials and additives, making the gears easy to clean and preventing the microbial growth that leads to contamination.

-

Compliance: Our production meets international food safety standards, supported by our TÜV Rheinland ISO 9001 certification.

3. Integrated Protection: The 400μm Weather-Resistant Shield

While the gear teeth are polished for sanitary use, the external housing and structural connectors require a different kind of protection. Yancheng ACE Surface Treatment Technology provides a heavy-duty powder coating with a one-time thickness of 400μm. This ensures that the non-contact areas of the machinery are fully protected against the humid and corrosive environments typical of feed processing plants.

4. Technical Specifications & Material Compliance

| Component Category | Typical Materials | Key Application |

| Pellet Mill Drive Rings | 304, 316L, 17-4 PH | High-torque raw material pelleting |

| Mixer Transmission Rings | Stainless Steel / Alloy Steel | Precise raw material blending |

| Custom Drive Gears | 18CrNiMo7-6 (Forged) | High-speed, low-noise transmission |

| Sanitary Flange Rings | 316L Stainless Steel | Secure, leak-proof equipment assembly |

5. Frequently Asked Questions (FAQ)

Q1: Why is stainless steel forging preferred over carbon steel for feed gear-rings?

A: Feed raw materials often contain moisture and acidic additives that quickly corrode carbon steel. By using compliant stainless steels (304, 316L) in our gear-ring forgings, we ensure the components resist erosion and prevent rust from contaminating the feed.

Q2: How does the "Ra ≤ 0.8 μm" finish impact the longevity of the machine?

A: Beyond hygiene, a smoother surface reduces friction during the tooth-meshing process. This leads to lower heat generation and less mechanical wear, directly reducing downtime and extending the maintenance intervals for your equipment.

Q3: Can ACE Group handle custom gear-ring designs for non-standard machine models?

A: Yes. Our Jiangsu facility is equipped with 1-meter and 1.5-meter vertical ring rolling machines. We specialize in customized production, allowing us to adapt to specific machine geometries while maintaining the high-strength properties of a forged ring.

Q4: How do you verify the quality of the gear teeth after forging?

A: We implement strict Non-Destructive Testing (NDT), including ultrasonic and magnetic particle testing, followed by precise dimensional inspection in our machining workshop to ensure every gear tooth meets the exact profile required for efficient transmission.

English

English 中文简体

中文简体