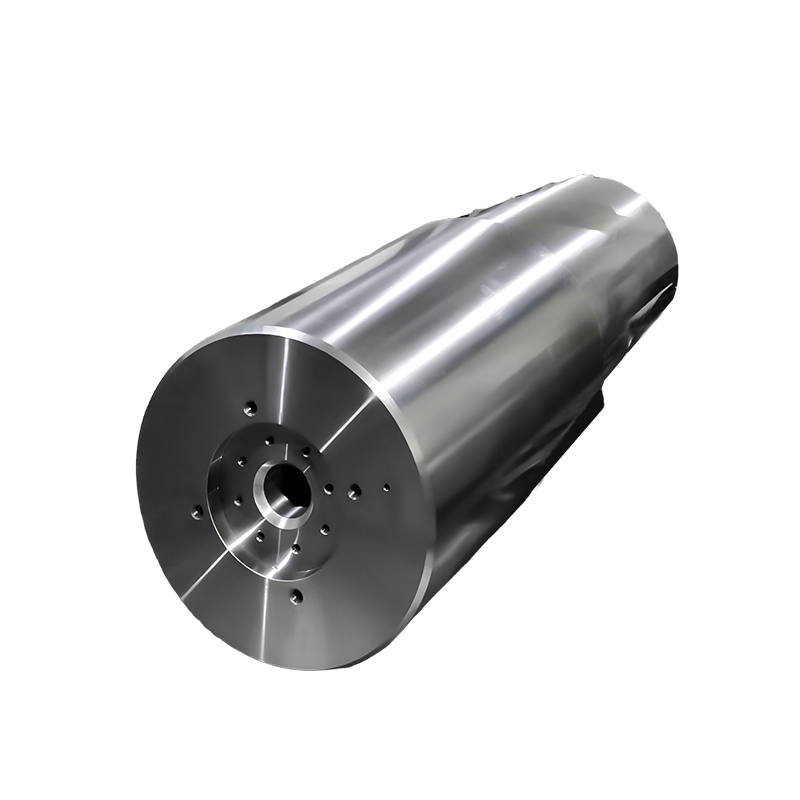

Crusher Forgings Supplier

Applications

Applied to key components of mining and metallurgical equipment, such as crushing, excavation, and rolling machinery.

Manufacturing Process

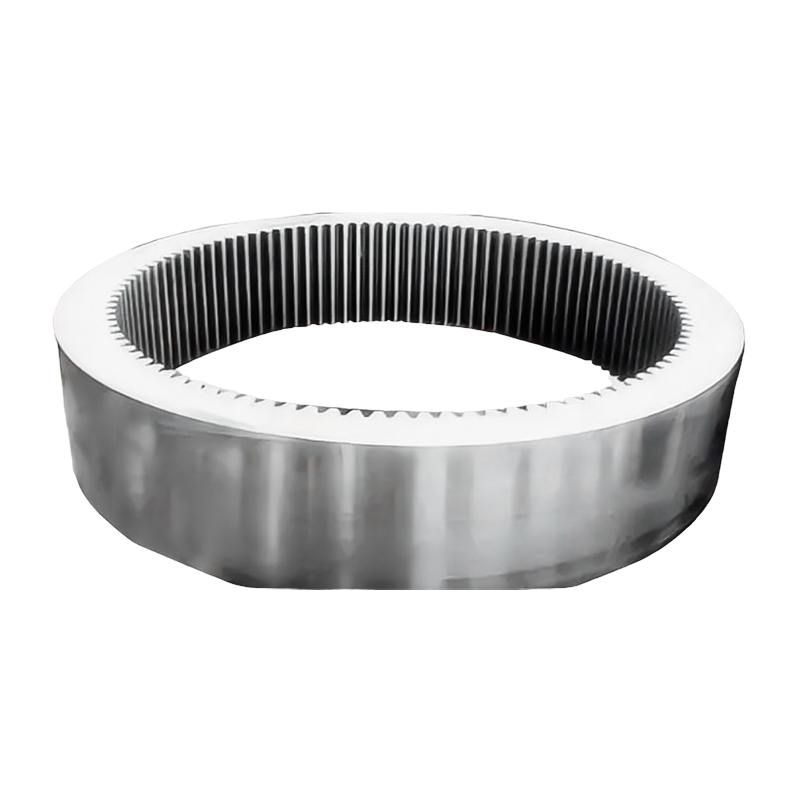

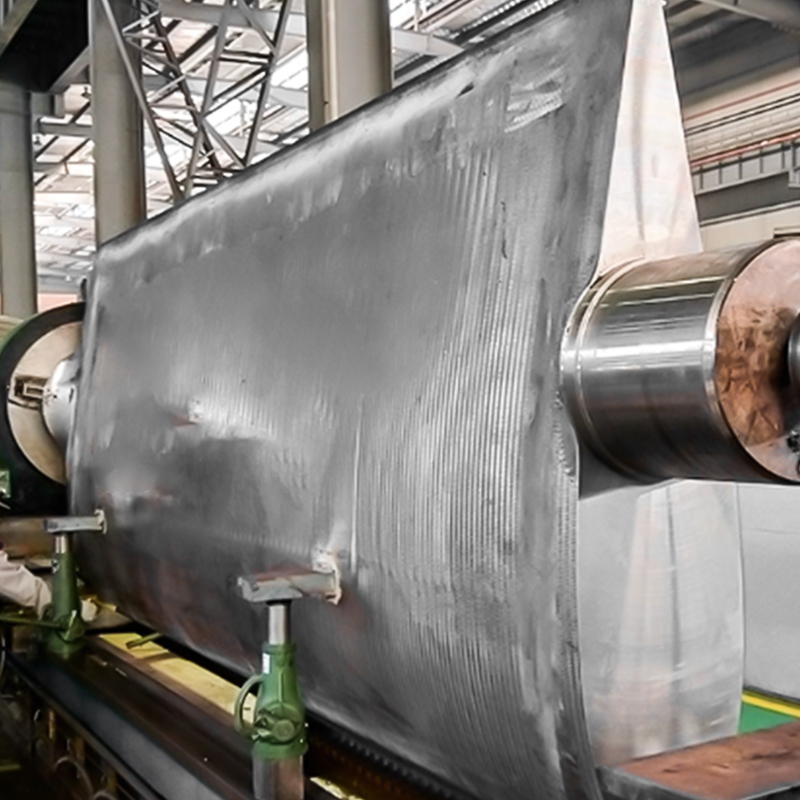

Manufactured using wear-resistant alloy materials, they undergo forging and precise heat treatment processes to optimize internal structure, enhance hardness, and toughness. Strict quality control measures are implemented throughout the production process.

Advantages

Excellent Durability & Impact Resistance: The components are wear-resistant and impact-resistant, capable of withstanding heavy loads and harsh operating conditions.

Stable High-Temperature Performance: They maintain good high-temperature strength stability, adapting to the high-temperature working environment in metallurgical processes (e.g., rolling, smelting).

Efficiency & Longevity Enhancement: Effectively improve equipment operation efficiency and service life, providing strong support for efficient production in the mining and metallurgical industry.

About Us

ACE Group is a comprehensive enterprise group focused on the heavy industrial manufacturing sector, serving as a China Crusher Forgings Supplier and Crusher Forgings Company. Its business spans forging, heat treatment, precision machining, welded structures, and heavy-duty power & free chain spraying production. This integrated layout covers the core production processes of the industrial machinery industry, combining technological strength with large-scale production capabilities.

Core Subsidiaries Details:

Jiangsu ACE Energy Technology Co., Ltd.: The group's core production base, officially commencing operations in November 2025. It occupies 55 acres with a total floor area exceeding 50,018 square meters. The factory is equipped with 3-ton, 5-ton, and 15-ton electro-hydraulic hammers; 1-meter and 1.5-meter vertical ring rolling machines; energy-efficient natural gas heating furnaces; heat treatment resistance furnaces; quenching tanks; induction hardening equipment; machining centers; and other production equipment.

Yancheng ACE Machinery Co., Ltd.: Established in 2019, it occupies 20 acres with a floor area of 13,333 square meters. It possesses an integrated welding-straightening structural steel production line and a precision machining workshop.

Yancheng ACE Surface Treatment Technology Co., Ltd.: Operates a heavy-duty power & free chain large-scale powder coating production line. Focusing on professional surface treatment technology, One-time coating thickness achieves 400μm, providing reliable anti-corrosion and weather-resistant protective performance and appearance optimization solutions, enhancing the group's full life-cycle product services.

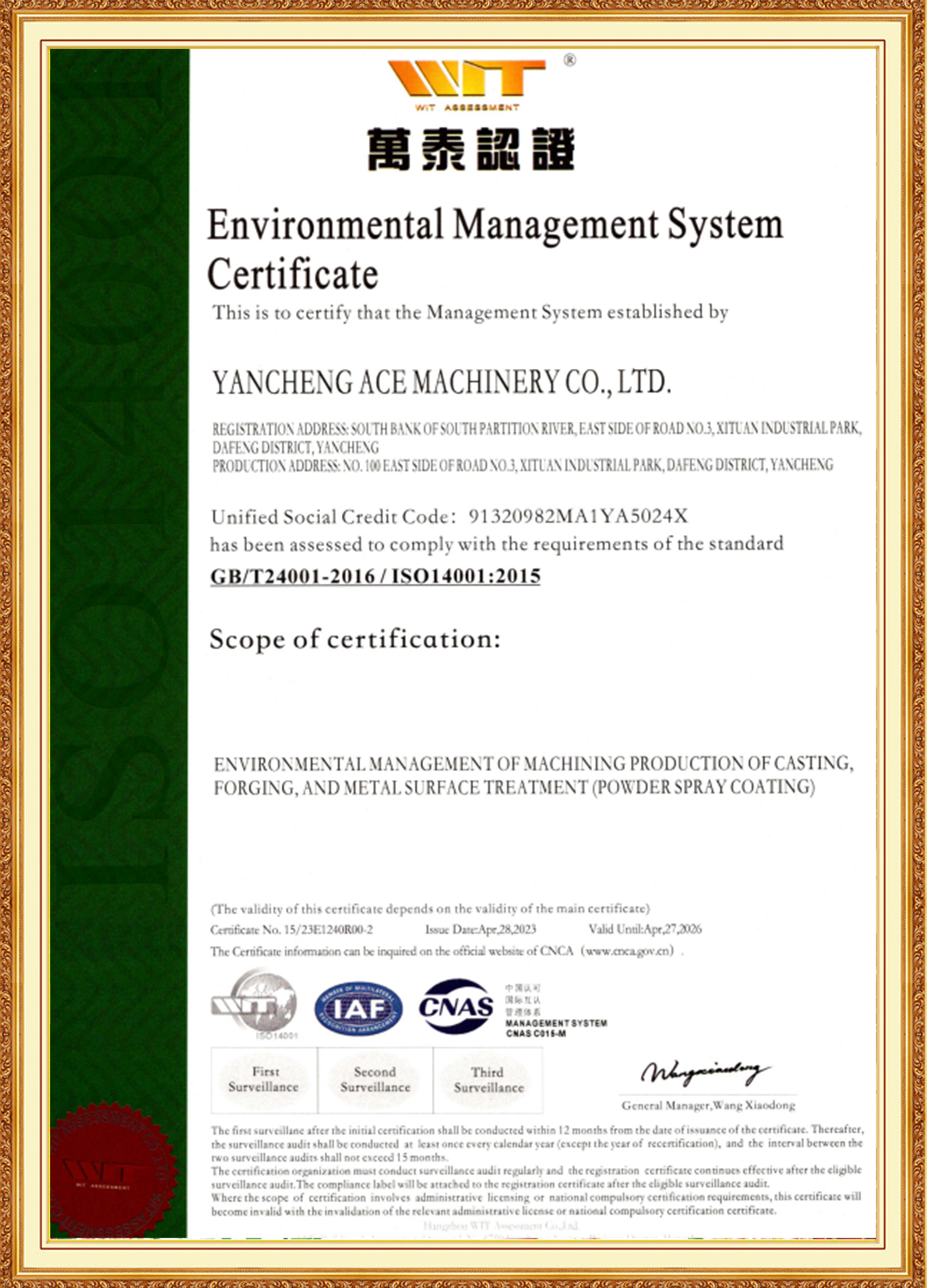

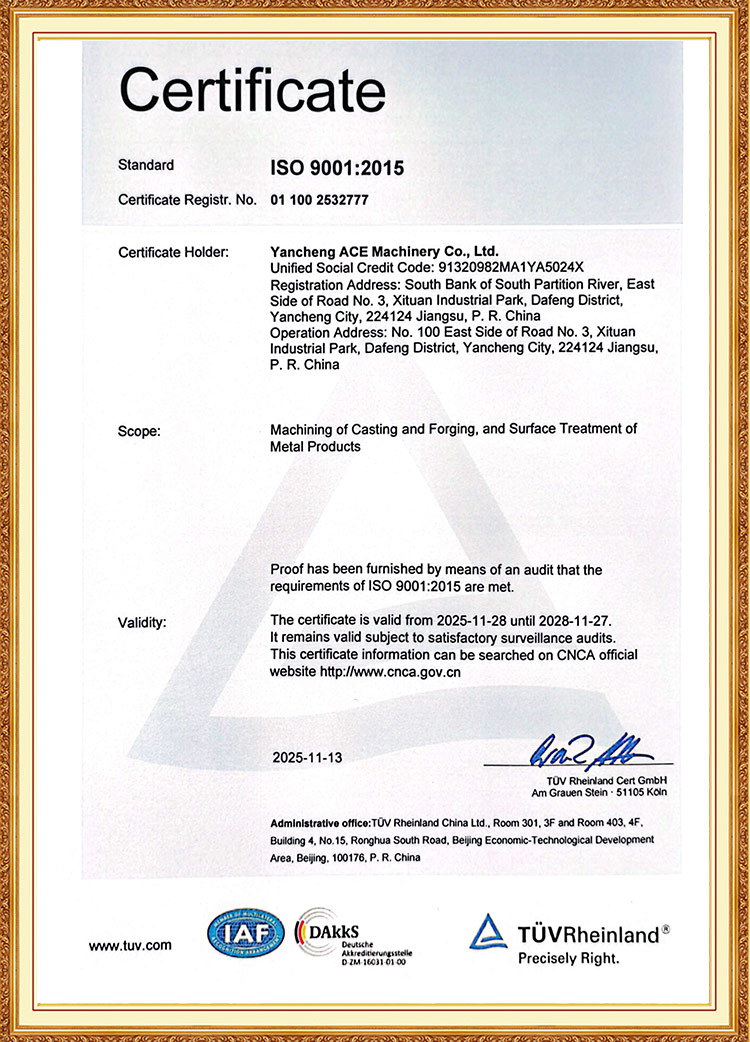

ACE Group is supported by a management team of young key members who are experienced in materials, heat treatment, machining, and surface treatment industries. They are well-versed in international and domestic standards, pioneering, and committed to innovation. The subsidiary ACE Machinery has passed TÜV Rheinland ISO 9001 Quality Management System certification, as well as ISO 14001, 45001, and 50001 system certifications. It is recognised as a Specialised, Refined, Unique, and Innovative Enterprise, a National High-Tech Enterprise, and holds a 3A-level enterprise credit rating.

Relying on integrated MES and ERP management systems, the integration of informatisation and industrialisation, data cloud storage, and aiming to build a modern, energy-efficient enterprise, the group maintains a comprehensive inspection system. It possesses inspection tools, non-destructive testing equipment, and qualified personnel, implementing strict controls from material internal quality to appearance and dimensions. All outgoing products undergo 100% inspection, adhering to the business philosophy of pursuing 100% qualified outgoing products and zero customer complaints. A CNAS-standard laboratory will be established to provide scientific testing support for quality control during production and technological R&D, thereby enhancing product quality and technological innovation.

In the future, ACE Group will continue to leverage the technical advantages and industrial synergies of its subsidiaries. Through standardised production, specialised technology, integrated services, and a stringent quality control system, it is committed to providing efficient and reliable industrial manufacturing solutions for global clients, steadily advancing towards becoming a leading comprehensive manufacturing service provider in the industry.

Certificate

-

Enterprise Credit Evaluation AAA

-

2024 Specialized, Refined, Distinctive, and Innovative Enterprise Certificate

-

2023 High-Tech Enterprise Certificate

-

ISO50001 Energy Management System

-

ISO 45001 Occupational Health and Safety Management System

-

ISO 14001 Environmental Management System

-

ISO 9001 Quality Management System

News

-

Company News 2026-01-25

After 6 months of precision engineering and collaboration, we are proud to announce the completion of our 700m rail supply for the Berendrechtsluis Lock renovation project at the Port of Antwerp-Bruges, Europe's largest integrated port. The final container, carrying 15 pieces of our 34CrNiMo6 QT T-type heavy-duty T-typ...

View More -

News 2026-01-19

On January 17, 2026, the inaugural annual gala of Jiangsu ACE Energy Technology Co., Ltd. was triumphantly held in an atmosphere brimming with enthusiasm. Over 160 attendees, including distinguished guests from various sectors, partners, government representatives, as well as the company's employees and their families,...

View More -

Company News 2025-11-12

With a resounding clang of the hammer, a new journey begins! Recently, the grand opening ceremony of Jiangsu ACE Energy Co., Ltd.'s forging base and the launch ceremony for the "first hammer" production were held in the Dafeng Economic Development Zone Industrial Park, Jiangsu Province. As ACE Energy Chairman Zhai Liuy...

View More

Crusher Forgings KNOWLEDGE

In the abrasive world of mining and metal smelting, equipment components face a brutal combination of high-velocity impact, extreme pressure, and elevated temperatures. Standard cast parts often fail prematurely under these conditions, leading to costly downtime. To ensure continuous production in excavation and rolling machinery, the industry demands crusher forgings that possess superior metallurgical density and structural integrity.

At ACE Group, we synthesize heavy-duty forging power with advanced material science. Our integrated production—from the 15-ton electro-hydraulic hammers at Jiangsu ACE Energy Technology to our precision heat treatment resistance furnaces—ensures that every component is engineered to thrive in the most hostile industrial environments.

1. The Forging Edge: Impact Resistance & Core Toughness

The primary failure mode in crushing equipment is "brittle fracture" caused by sudden shock loads. While casting can leave internal microscopic voids, the forging process at ACE Group compresses the metal, refining the internal microstructure to eliminate porosity.

Why Forged Crusher Components?

-

Grain Refinement: Forging aligns the metal's grain flow to the shape of the part, providing maximum resistance to the impact forces encountered during rock crushing.

-

Optimized Internal Structure: Our precise heat treatment optimizes the balance between surface hardness (to resist wear) and core toughness (to prevent snapping).

| Performance Metric | ACE Group Crusher Forgings | Standard Cast Wear Parts |

| Material Density | Ultra-high (Void-free) | Variable (Prone to internal shrinkage) |

| Impact Toughness | Exceptional ($A_k$ values 2-3x higher) | Moderate (Risk of catastrophic cracking) |

| Thermal Stability | Maintains strength at high temps | Prone to thermal fatigue and warping |

| Service Life | Extended 40% - 60% | Standard |

2. Specialized Manufacturing for Harsh Environments

Mining and metallurgical processes require more than just "hard" metal; they require stable, wear-resistant alloy materials.

-

Advanced Forging: Utilizing 15-ton electro-hydraulic hammers, we achieve the deep penetration necessary for large-scale mining shafts, hammers, and rollers.

-

Precision Heat Treatment: Our resistance furnaces and quenching tanks allow us to perform precise Quenching & Tempering (Q&T) and Induction Hardening. This ensures the parts can withstand the high-temperature working environment of smelting and rolling without losing structural stability.

-

Precision Machining: At Yancheng ACE Machinery, we provide the final tolerances required for high-efficiency assembly, ensuring perfect fitment in complex crushing mechanisms.

3. Surface Protection: The 400μm Anti-Corrosion Barrier

Mining sites are often acidic or highly saline. Yancheng ACE Surface Treatment Technology utilizes a heavy-duty power & free chain coating line to apply a one-time coating thickness of 400μm. This ultra-thick layer provides reliable anti-corrosion and weather-resistant protection, ensuring that parts remain intact during transit, outdoor storage, and operation.

4. Technical Specifications & Applications

| Component Category | Typical Materials | Key Mining & Metallurgical Applications |

| Crusher Main Shafts | 42CrMo4, 34CrNiMo6 | Primary Gyratory and Cone Crushers |

| Hammers & Liners | High-Mn Steel, Alloy Steel | Impact Crushers & Grinding Mills |

| Forged Rollers | 9Cr2Mo, 86CrMoV7 | Metallurgical Rolling & Smelting Machinery |

| Excavator Pins/Shafts | 40Cr, 42CrMo | Heavy-duty Excavation & Earthmoving |

5. Frequently Asked Questions (FAQ)

Q1: Why are crusher forgings better than castings for heavy-duty mining?

A: Castings are susceptible to "internal defects" like gas pockets, which act as stress-concentration points. Under the heavy loads of a crusher, these pockets lead to cracks. Forging mechanically deforms the metal, closing these voids and creating a "tough" fiber-like structure that is nearly impossible to shatter.

Q2: How does ACE Group manage the high-temperature requirements of metallurgical equipment?

A: We use specialized wear-resistant alloy materials with high thermal stability. Through our precise heat treatment processes, we stabilize the microstructure of the steel so it maintains its hardness and yield strength even when exposed to the radiant heat of smelting and rolling processes.

Q3: Can ACE Group handle customized production for non-standard equipment?

A: Yes. As a Specialized, Refined, Unique, and Innovative Enterprise, we specialize in customized production. Our facility occupies over 50,018 square meters and is equipped with a range of electro-hydraulic hammers (3t to 15t) to handle various sizes and geometries for specific project needs.

Q4: What quality standards do your products meet?

A: Our subsidiaries are certified by TÜV Rheinland ISO 9001 and maintain ISO 14001, 45001, and 50001 certifications. Every part undergoes strict inspection, including ultrasonic flaw detection, to ensure it meets international industrial standards.

English

English 中文简体

中文简体