About Us

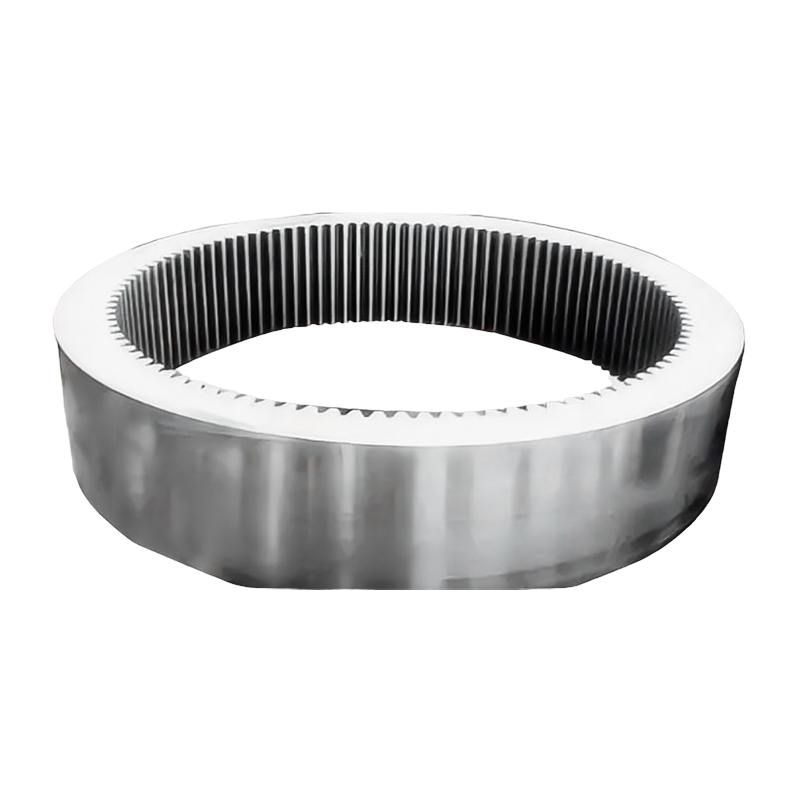

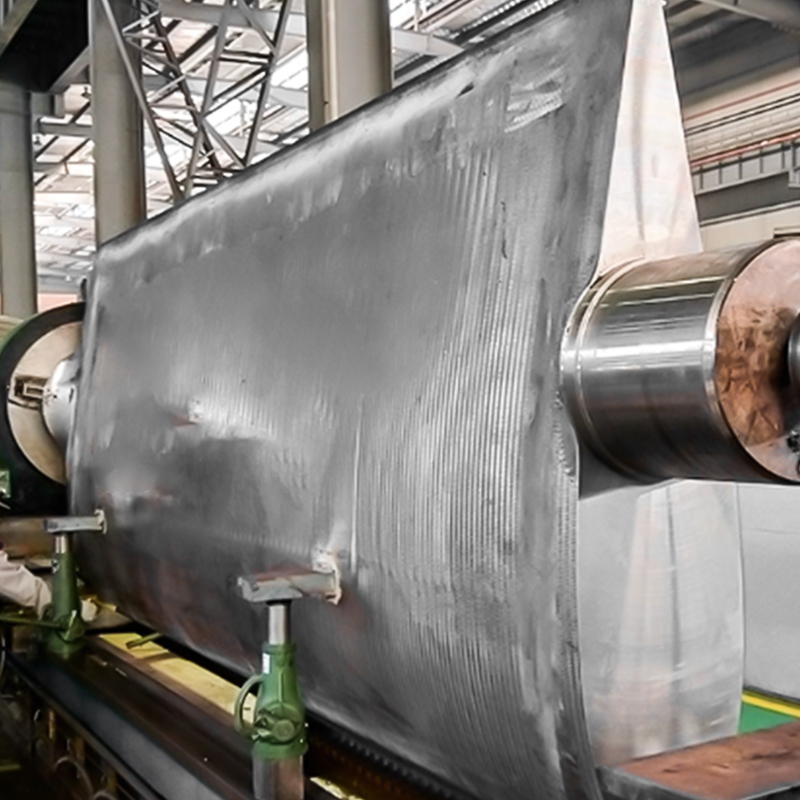

ACE Group is a comprehensive enterprise group focused on the heavy industrial manufacturing sector, serving as a China Welding Fabrication Manufacturers and Welding Fabrication Factory. Its business spans forging, heat treatment, precision machining, welded structures, and heavy-duty power & free chain spraying production. This integrated layout covers the core production processes of the industrial machinery industry, combining technological strength with large-scale production capabilities.

Core Subsidiaries Details:

Jiangsu ACE Energy Technology Co., Ltd.: The group's core production base, officially commencing operations in November 2025. It occupies 55 acres with a total floor area exceeding 50,018 square meters. The factory is equipped with 3-ton, 5-ton, and 15-ton electro-hydraulic hammers; 1-meter and 1.5-meter vertical ring rolling machines; energy-efficient natural gas heating furnaces; heat treatment resistance furnaces; quenching tanks; induction hardening equipment; machining centers; and other production equipment.

Yancheng ACE Machinery Co., Ltd.: Established in 2019, it occupies 20 acres with a floor area of 13,333 square meters. It possesses an integrated welding-straightening structural steel production line and a precision machining workshop.

Yancheng ACE Surface Treatment Technology Co., Ltd.: Operates a heavy-duty power & free chain large-scale powder coating production line. Focusing on professional surface treatment technology, One-time coating thickness achieves 400μm, providing reliable anti-corrosion and weather-resistant protective performance and appearance optimization solutions, enhancing the group's full life-cycle product services.

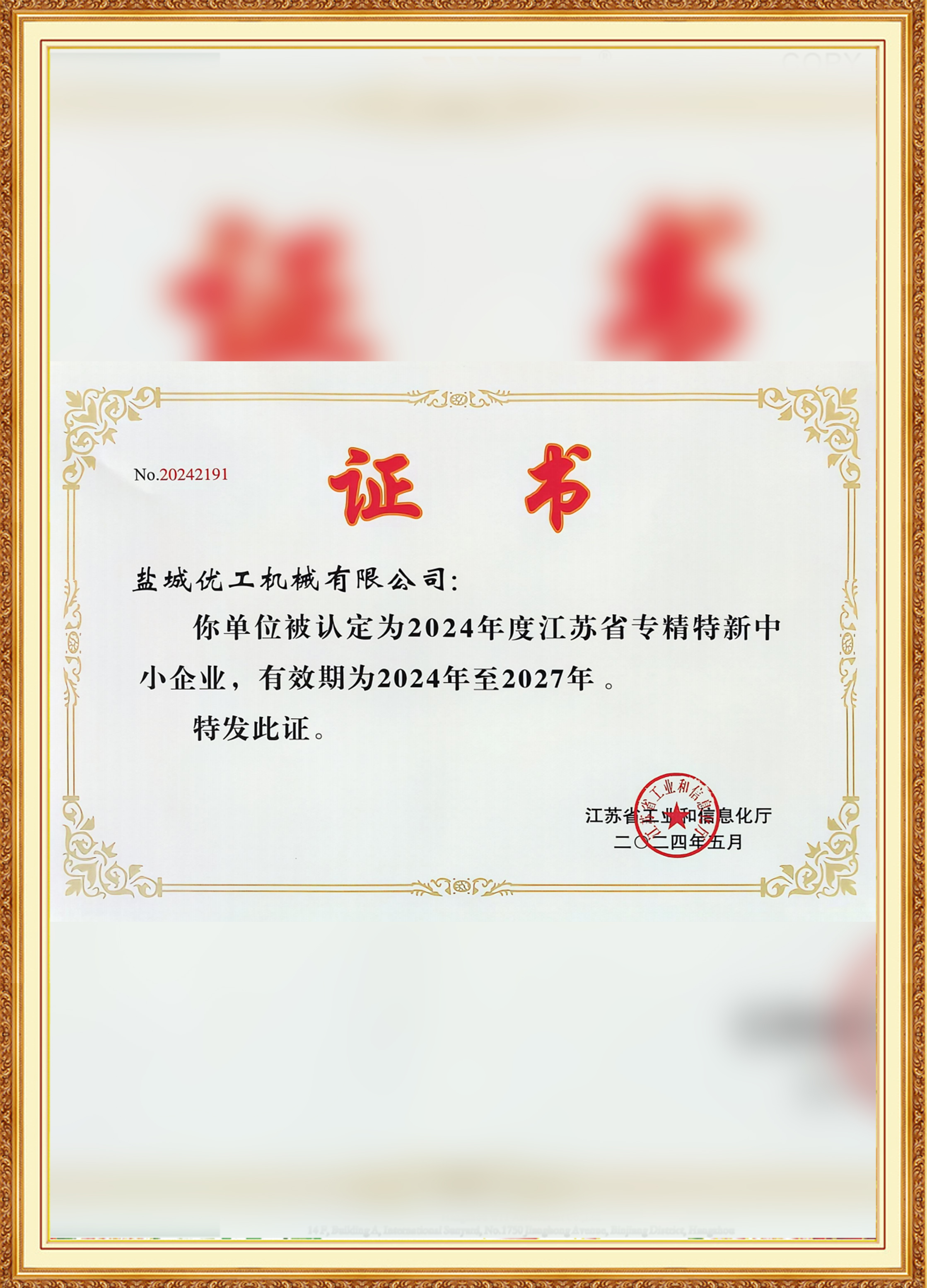

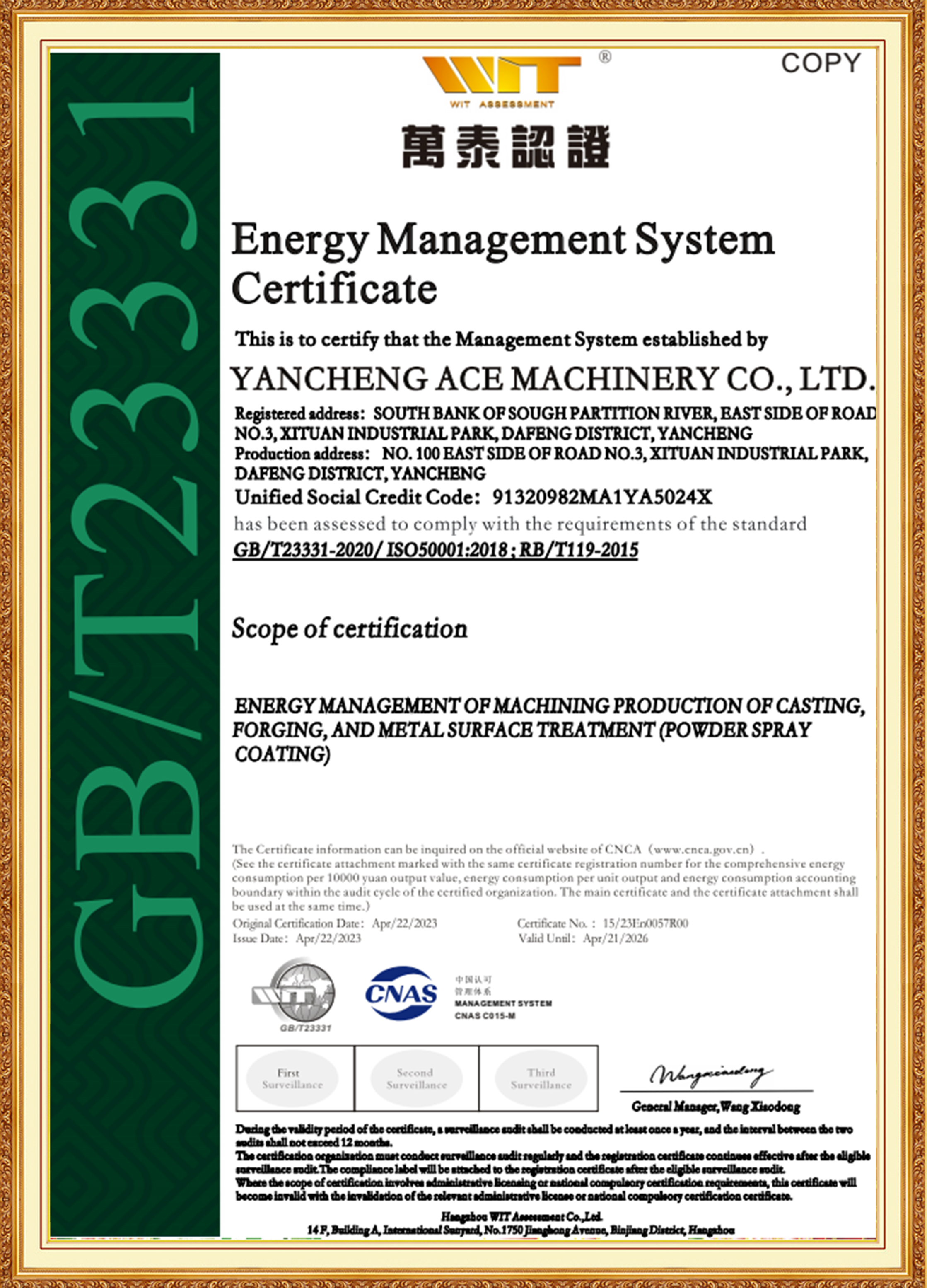

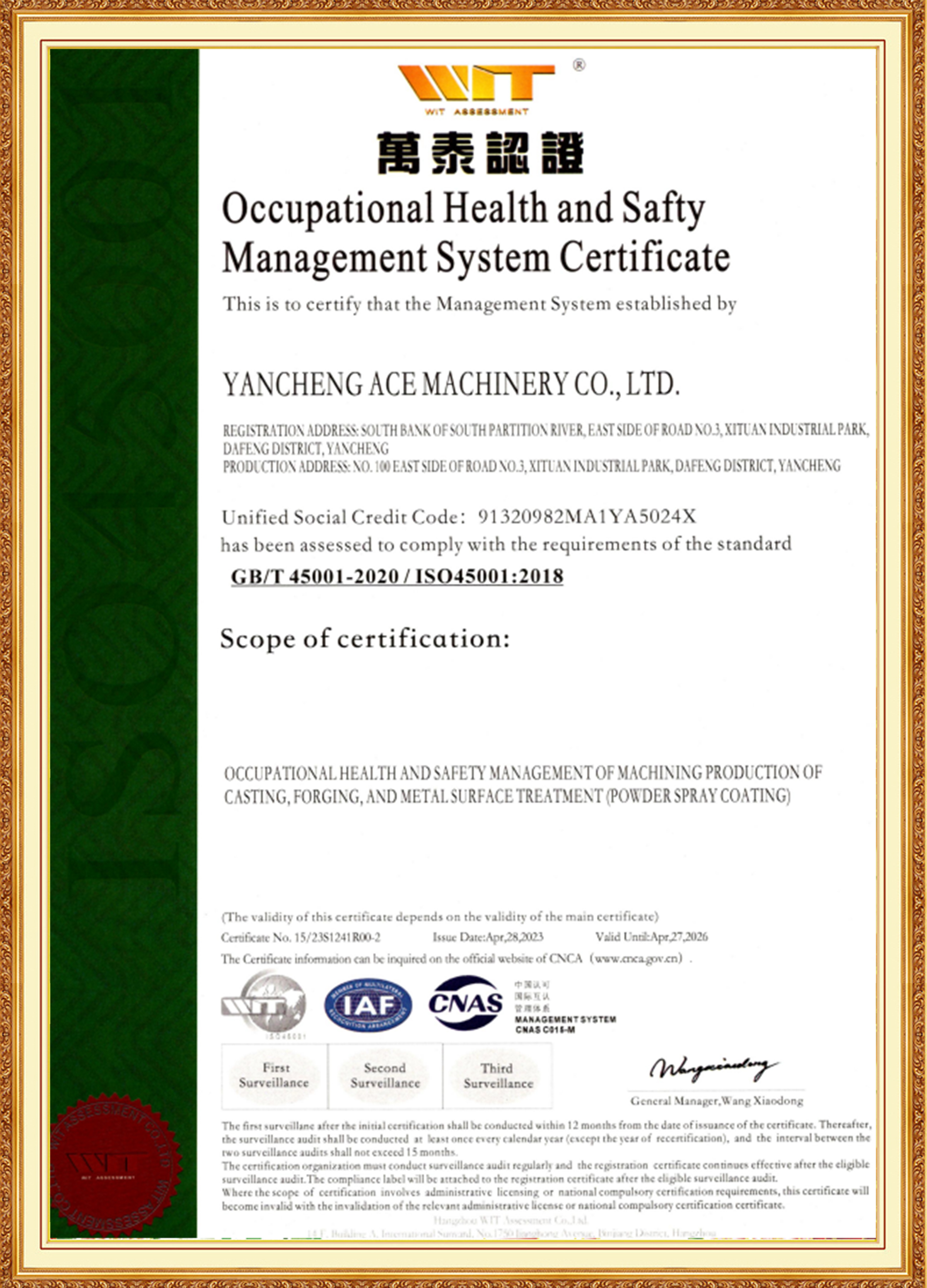

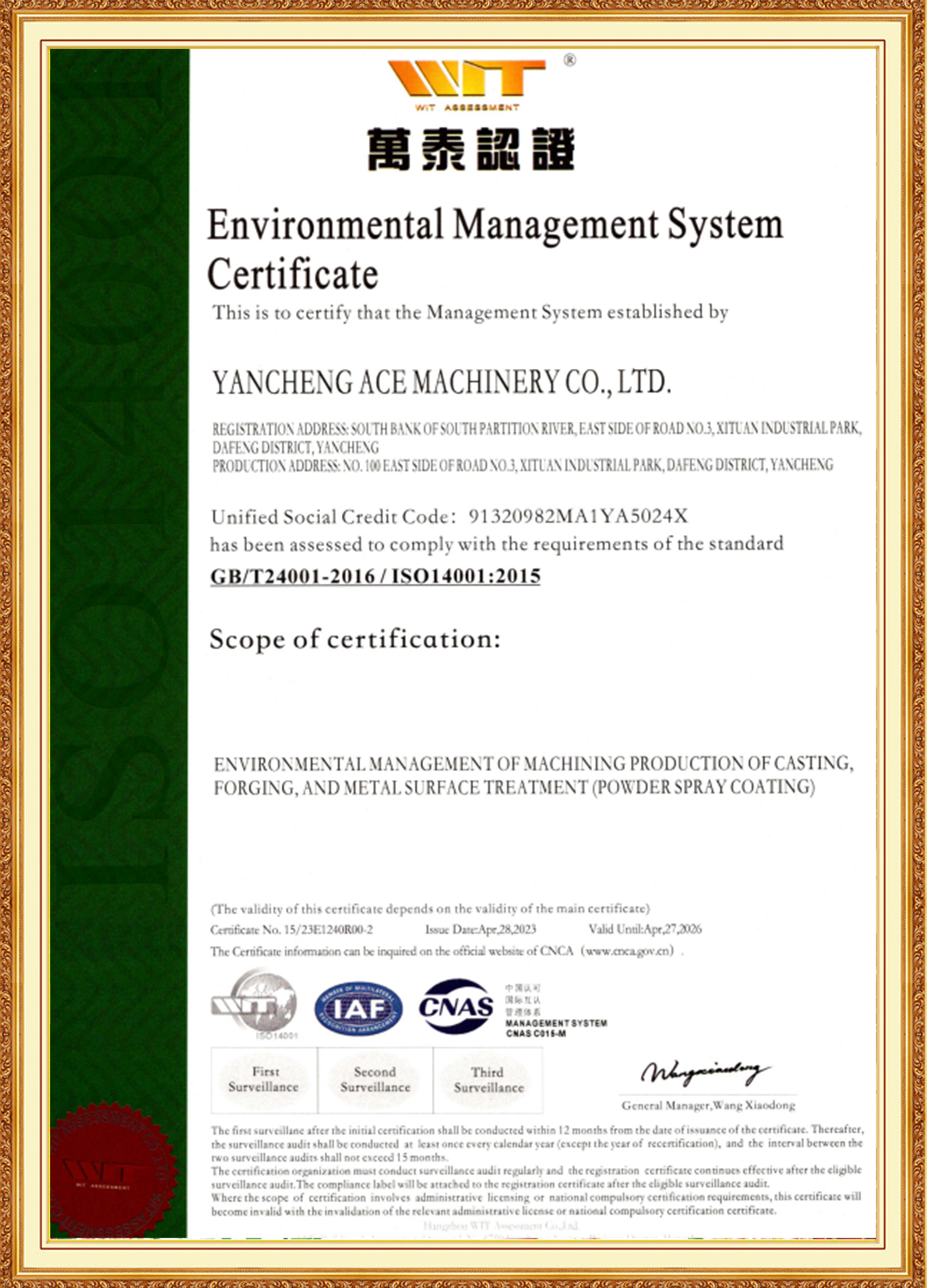

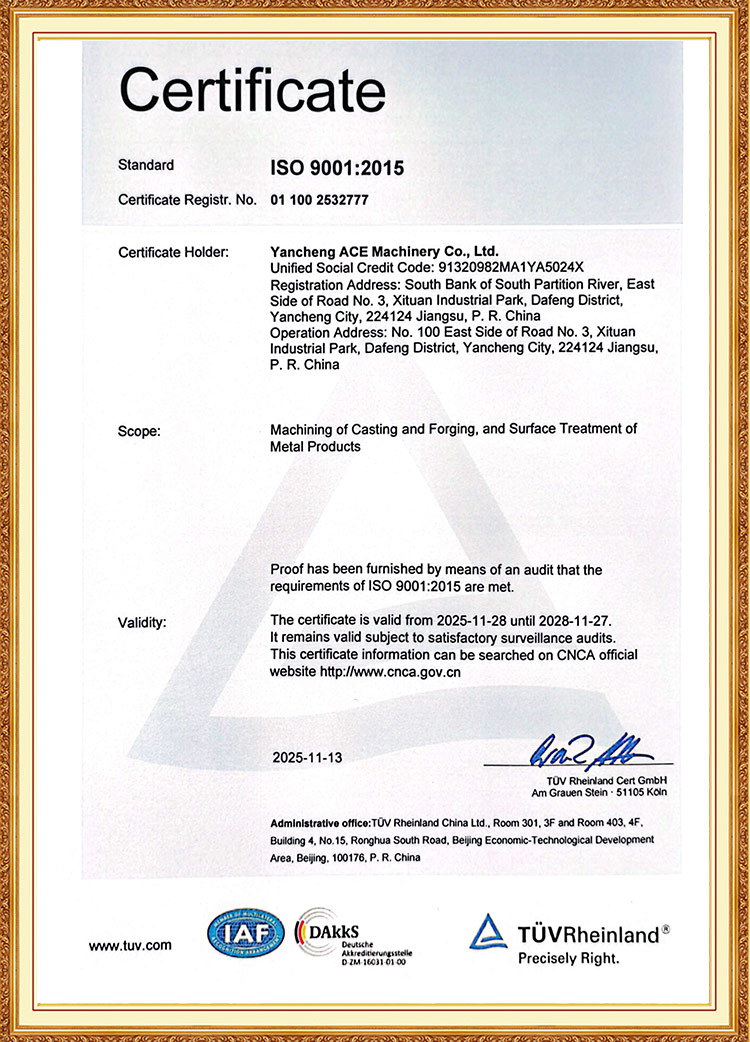

ACE Group is supported by a management team of young key members who are experienced in materials, heat treatment, machining, and surface treatment industries. They are well-versed in international and domestic standards, pioneering, and committed to innovation. The subsidiary ACE Machinery has passed TÜV Rheinland ISO 9001 Quality Management System certification, as well as ISO 14001, 45001, and 50001 system certifications. It is recognised as a Specialised, Refined, Unique, and Innovative Enterprise, a National High-Tech Enterprise, and holds a 3A-level enterprise credit rating.

Relying on integrated MES and ERP management systems, the integration of informatisation and industrialisation, data cloud storage, and aiming to build a modern, energy-efficient enterprise, the group maintains a comprehensive inspection system. It possesses inspection tools, non-destructive testing equipment, and qualified personnel, implementing strict controls from material internal quality to appearance and dimensions. All outgoing products undergo 100% inspection, adhering to the business philosophy of pursuing 100% qualified outgoing products and zero customer complaints. A CNAS-standard laboratory will be established to provide scientific testing support for quality control during production and technological R&D, thereby enhancing product quality and technological innovation.

In the future, ACE Group will continue to leverage the technical advantages and industrial synergies of its subsidiaries. Through standardised production, specialised technology, integrated services, and a stringent quality control system, it is committed to providing efficient and reliable industrial manufacturing solutions for global clients, steadily advancing towards becoming a leading comprehensive manufacturing service provider in the industry.

Certificate

-

Enterprise Credit Evaluation AAA

-

2024 Specialized, Refined, Distinctive, and Innovative Enterprise Certificate

-

2023 High-Tech Enterprise Certificate

-

ISO50001 Energy Management System

-

ISO 45001 Occupational Health and Safety Management System

-

ISO 14001 Environmental Management System

-

ISO 9001 Quality Management System

News

-

Company News 2026-01-25

After 6 months of precision engineering and collaboration, we are proud to announce the completion of our 700m rail supply for the Berendrechtsluis Lock renovation project at the Port of Antwerp-Bruges, Europe's largest integrated port. The final container, carrying 15 pieces of our 34CrNiMo6 QT T-type heavy-duty T-typ...

View More -

News 2026-01-19

On January 17, 2026, the inaugural annual gala of Jiangsu ACE Energy Technology Co., Ltd. was triumphantly held in an atmosphere brimming with enthusiasm. Over 160 attendees, including distinguished guests from various sectors, partners, government representatives, as well as the company's employees and their families,...

View More -

Company News 2025-11-12

With a resounding clang of the hammer, a new journey begins! Recently, the grand opening ceremony of Jiangsu ACE Energy Co., Ltd.'s forging base and the launch ceremony for the "first hammer" production were held in the Dafeng Economic Development Zone Industrial Park, Jiangsu Province. As ACE Energy Chairman Zhai Liuy...

View More

Welding Fabrication KNOWLEDGE

I. Core Principles of Welding

- Fusion Welding: The base metal melts locally, and filler material can be used as needed. The weld seam is formed by the solidification of molten metal.

- Pressure Welding: Pressure is applied to ensure tight contact between the workpiece surfaces. Atomic bonding is achieved through plastic deformation, and some processes require auxiliary heating.

- Brazing: Only the brazing filler metal melts without melting the base metal. The molten filler metal wets the base metal surface and fills the gaps via capillary action to form a connection.

II. Classification and Characteristics of Common Welding Methods

1. Fusion Welding (Most Widely Used)

| Welding Method | Core Characteristics | Application Scenarios |

|---|---|---|

| Shielded Metal Arc Welding (SMAW) | Simple equipment, flexible operation; welding electrodes serve as both electrode and filler material, relying on manual operation | Maintenance, small-batch production, on-site welding of steel structures |

| Gas Metal Arc Welding (GMAW/MIG) & Gas Tungsten Arc Welding (GTAW/TIG) | Argon, carbon dioxide and other gases are used to isolate air and prevent weld oxidation; MIG welding offers high efficiency, while TIG welding ensures superior weld quality | MIG Welding: Automotive body panels, aluminum alloy components; TIG Welding: Stainless steel, precision parts |

| Submerged Arc Welding (SAW) | The electric arc burns under a layer of flux, resulting in good weld formation, high efficiency and no arc light pollution | Batch welding of thick steel plates, e.g., ship hulls, pressure vessels |

| Plasma Arc Welding (PAW) | Uses high-temperature plasma arc with high energy density, capable of welding thinner or thicker workpieces | Thin-walled components in aerospace, welding of special metals |

2. Pressure Welding

- Resistance Welding: Utilizes resistance heat generated by electric current passing through the contact surfaces of workpieces, with simultaneous pressure application to complete welding. It is divided into spot welding, seam welding and butt welding. Spot welding is widely used in automotive body welding; seam welding is applied to sealed components such as fuel tanks.

- Friction Welding: Generates heat through high-speed friction between workpieces. When the contact surfaces reach a plastic state, pressure is applied for welding. It features stable joint quality and is suitable for welding dissimilar metals, e.g., butt welding of shaft parts.

3. Brazing

- Torch Brazing: Uses oxyacetylene flame for heating, featuring simple operation; Vacuum Brazing: Performed in a vacuum environment to avoid oxidation, suitable for precision and complex components such as aero-engine blades.

- The advantage of brazing is minimal welding deformation, while the disadvantage is that the joint strength is generally lower than that of the base metal.

III. Welding Materials

- Welding Electrodes: Exclusive for SMAW, consisting of a core wire (filler metal) and a coating. The coating functions to stabilize the arc, form slag, deoxidize and alloy the weld metal.

- Welding Wires: Used in gas-shielded welding and submerged arc welding, divided into solid wires and flux-cored wires. Flux-cored wires have built-in protective components and offer stronger adaptability.

- Welding Flux: Applied in submerged arc welding, categorized into fused flux and non-fused flux. It plays roles in protecting the weld pool, deoxidizing and improving weld formation.

- Brazing Filler Metals: Specialized for brazing, with a melting point lower than that of the base metal. Common types include copper-based and silver-based brazing filler metals.

IV. Key Elements of Welding Technology

- Welding Parameters: Including welding current, voltage, welding speed, shielding gas flow rate, etc. Parameters directly affect the weld penetration, formation and quality. For example, excessive current may cause burn-through, while insufficient current leads to insufficient penetration.

- Groove Design: For welding thick plates, grooves (such as V-groove, X-groove) need to be pre-processed to ensure full weld penetration and reduce incomplete penetration defects.

- Preheating and Post-heating: For crack-sensitive materials such as high-strength steel and cast iron, preheating before welding can reduce the cooling rate and avoid cold cracking; post-heating after welding can eliminate residual stress and improve microstructure and properties.

V. Welding Quality Inspection

Visual Inspection: Checks weld formation, dimensions and surface defects (e.g., porosity, cracks, undercut) with the naked eye or with the help of a magnifying glass.

- Non-Destructive Testing (NDT): Does not damage the workpiece, including Ultrasonic Testing (UT, for detecting internal defects), Radiographic Testing (RT, for detecting internal porosity and slag inclusion), Magnetic Particle Testing (MT, for detecting surface defects of ferromagnetic materials).

- Destructive Testing: Takes weld samples for tensile, bending and impact tests to evaluate the mechanical properties of the welded joint.

VI. Welding Safety and Protection

- Arc Light Radiation Protection: Ultraviolet and infrared rays in welding arc light can burn the skin and eyes, requiring the use of welding helmets and protective clothing.

- Harmful Gas Protection: Ozone, nitrogen oxides and other harmful gases are generated during welding, so good ventilation in the working environment must be ensured.

Electric Shock Protection: Welding equipment must be grounded, and operators need to wear insulating gloves and shoes.

VII. Frequently Asked Questions

Q1: Why are some metals (e.g., Aluminum) harder to weld than steel?

-

A: Aluminum has high thermal conductivity and rapid oxidation. It dissipates heat so quickly that forming a stable molten pool is difficult. Additionally, the aluminum oxide layer ($Al_2O_3$) has a melting point of over 2050°C, much higher than the metal itself (660°C). This usually requires AC TIG or specialized pulse MIG welding.

Q2: What is the Heat Affected Zone (HAZ) and why is it critical?

-

A: The HAZ is the area of base metal not melted, but whose microstructure has been altered by heat. This area can become brittle or lose strength due to the thermal cycle. Most structural failures, such as cracks, occur within the HAZ.

Q3: How is welding distortion caused and how can it be prevented?

-

A: Distortion is caused by uneven thermal expansion and contraction. Prevention methods include:

-

Pre-setting: Angling the parts in the opposite direction before welding.

-

Symmetric Welding: Welding from the center outward or in a balanced sequence.

-

Reducing Heat Input: Using high-energy-density processes like Laser welding.

-

Q4: Why is post-heating or "Hydrogen Release" necessary?

-

A: Hydrogen atoms can cause delayed cracking in the weld. Post-heating allows hydrogen to diffuse out of the metal, which is crucial for high-strength steels and thick plates.

Q5: Can robotic welding fully replace manual welding?

-

-

A: While robots excel in high-volume, standardized production (e.g., automotive), human welders remain irreplaceable for fieldwork, complex spatial joints, one-off custom jobs, and tasks requiring real-time sensory adjustment.

-

English

English 中文简体

中文简体