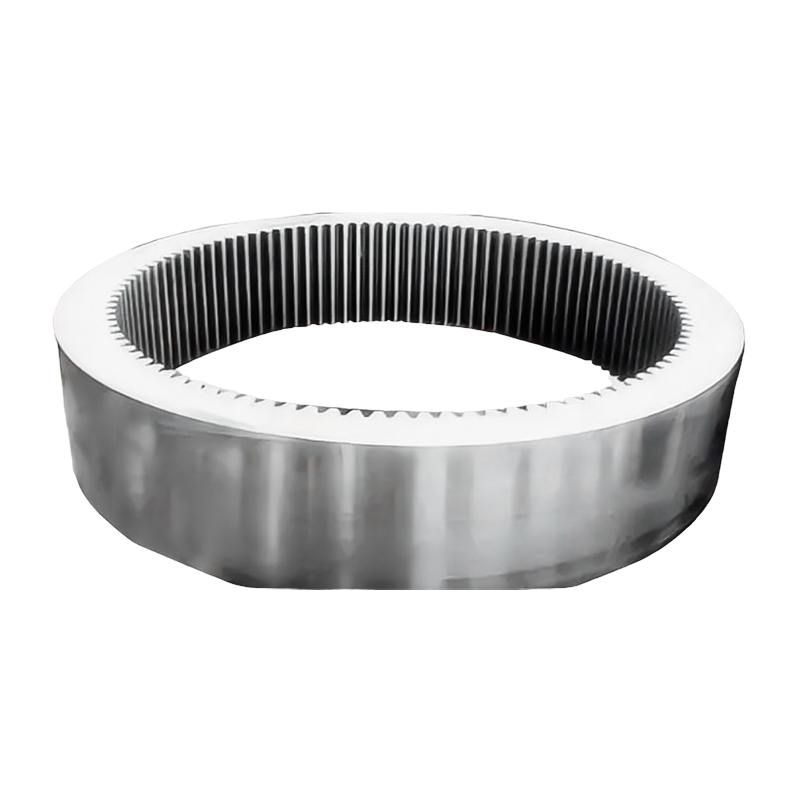

Stiffening Ring

In feed machinery—specifically for key parts such as the cylinder shells, rotor shafts, and conveying pipes of pellet mills, mixers, and crushers—stiffening rings are important auxiliary components designed to enhance structural performance. Their core functions revolve around "improving structural stability, extending equipment service life, and ensuring production safety."

Core Functions

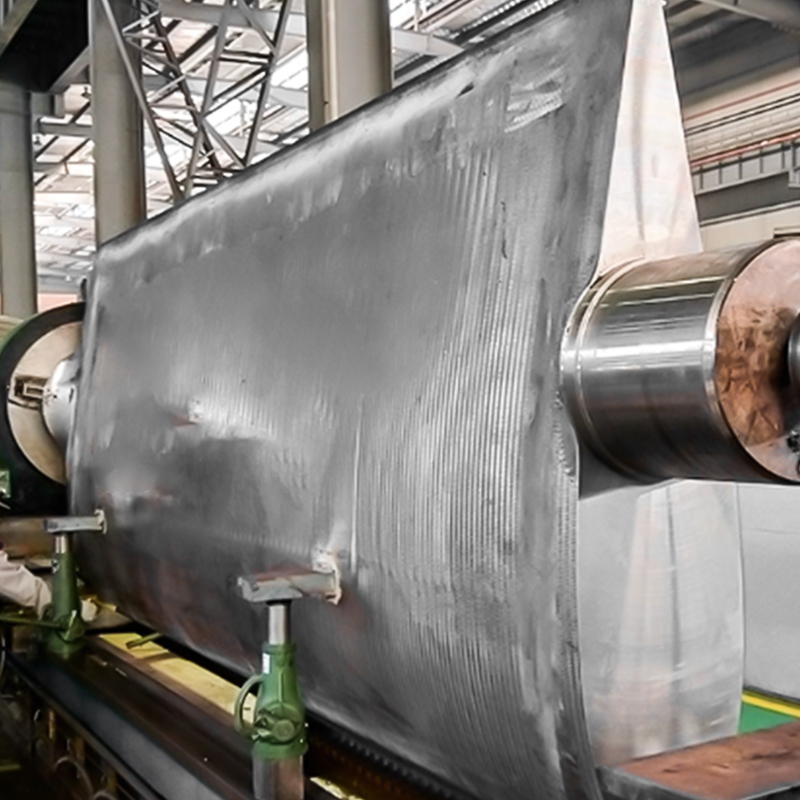

Restrain Structural Deformation: Prevent excessive deformation of components (e.g., cylinder shells, conveying pipes) during operation, ensuring the precision of feed processing equipment (critical for consistent product quality, such as pellet size uniformity).

Reduce Vibration and Resonance: Diminish vibrations generated by rotating parts (e.g., rotor shafts) and suppress resonance effects between components, thereby lowering operational noise and reducing wear caused by vibration.

Enhance Fatigue Resistance: Strengthen the structural integrity of key parts, enabling them to withstand long-term cyclic loads in continuous feed production. This significantly extends the service life of both the components and the entire equipment.

English

English