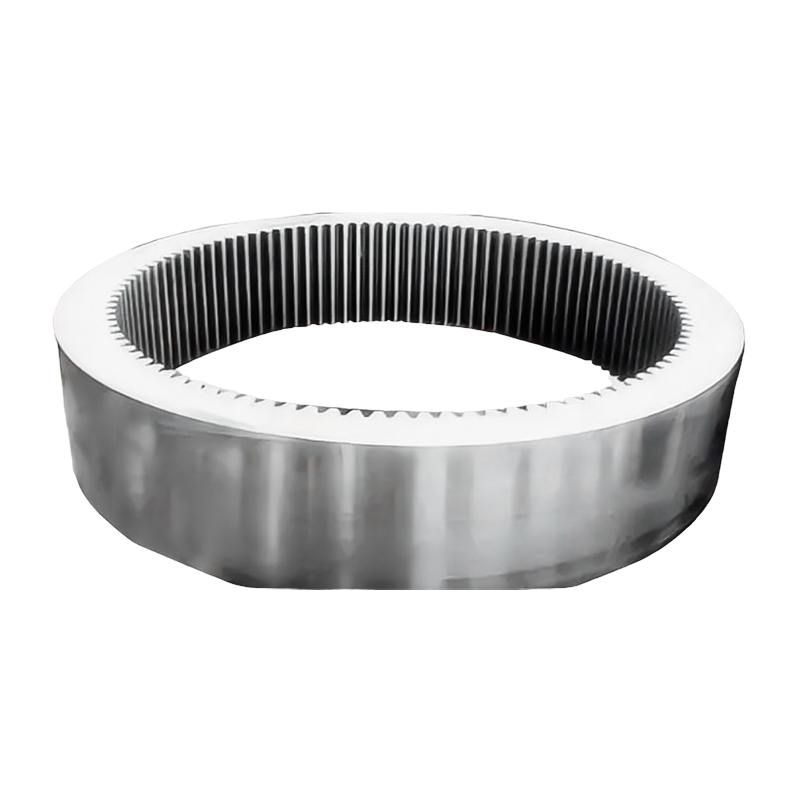

Wind Turbine 5MW-10MW 1st/2nd Stage Ring Gear

Made of high-purity alloy steel such as 18CrNiMo7-6, they undergo ring rolling forming and carburizing-quenching processes. With surface hardness reaching 58-62HRC and excellent core toughness, they feature strong impact resistance and wear resistance, adapting to high-power loads and boasting a service life of over 20 years. The tooth profile is precision-ground to grade 5-6 accuracy, ensuring stable transmission and low loss, thus guaranteeing power generation efficiency.

Core selling points lie in "high reliability + easy maintenance": The modular tooth block design allows single-block replacement, avoiding overall scrapping and significantly reducing operation and maintenance costs. They comply with IEC standards and adapt to harsh onshore/offshore working conditions.

Applied in the main gearboxes of 5MW-10MW wind turbines, they serve as the fixed end of the planetary transmission system, supporting stable meshing of planetary gears and efficiently transmitting torque, making them core components for long-term operation of large-capacity wind turbines.

English

English