Wind Turbine 5MW-10MW 1st/2nd/3rd Stage Sun Gear

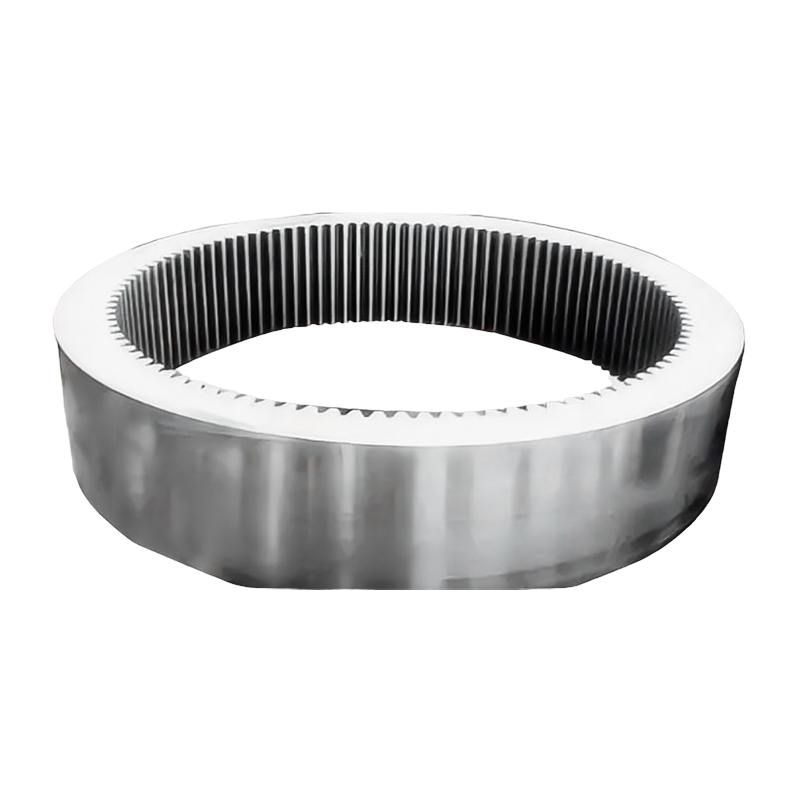

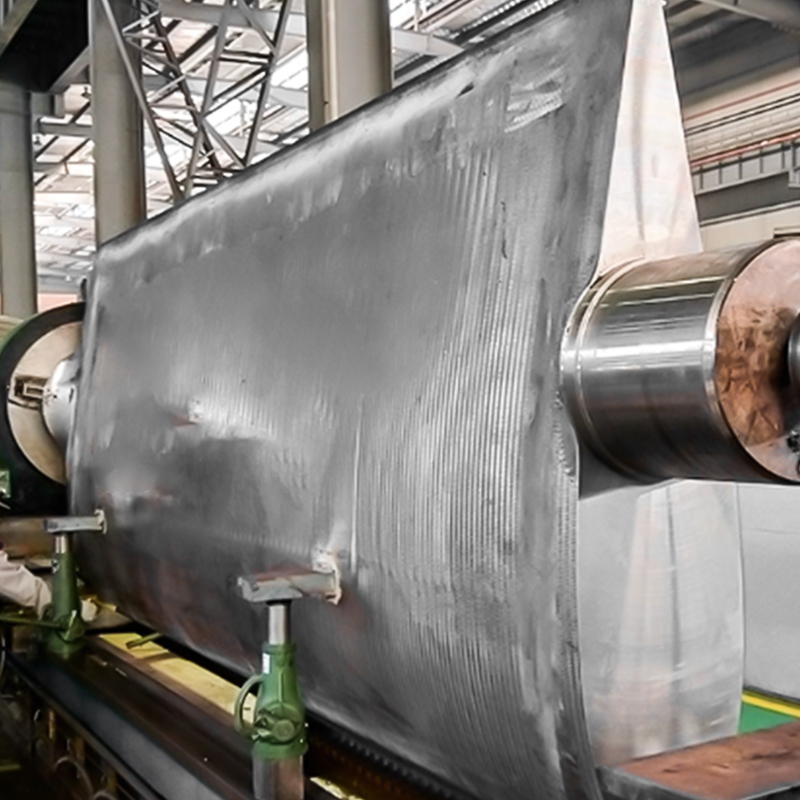

Planetary Gearbox planetary gears, sun gears, planet carriers, and ring gears are core components of the transmission system in wind turbine generators (primarily used in speed increasers). Their design and performance directly determine the power generation efficiency, reliability, and service life of wind power equipment.

They feature high load-bearing capacity and impact resistance, meeting the high-load requirements of wind power applications.

Structural optimizations include:

Adopting a multi-tooth meshing structure of "ring gear + planet carrier + sun gear," where the load is evenly distributed among multiple planetary gears.

Sun gears, planetary gears, and high-speed shafts are made of high-strength carburized steel such as 18CrNiMo7-6. After carburizing and quenching, the surface hardness reaches HRC58-62, while the core hardness is HRC30-35, balancing surface wear resistance with core toughness to withstand long-term alternating loads and impacts.

Wind power planet carriers and ring gears typically use an "integral forging" process (mostly made of 42CrMoA/42CrMo4) to avoid stress concentration in welded structures.

Some high-power models (above 3MW) adopt a "box structure + reinforcing rib" design, which reduces weight while enhancing rigidity. This ensures the "concentricity error of planetary gear shaft mounting holes is ≤0.02mm," preventing meshing eccentric loads between planetary gears, sun gears, and ring gears, and reducing tooth surface wear.

English

English