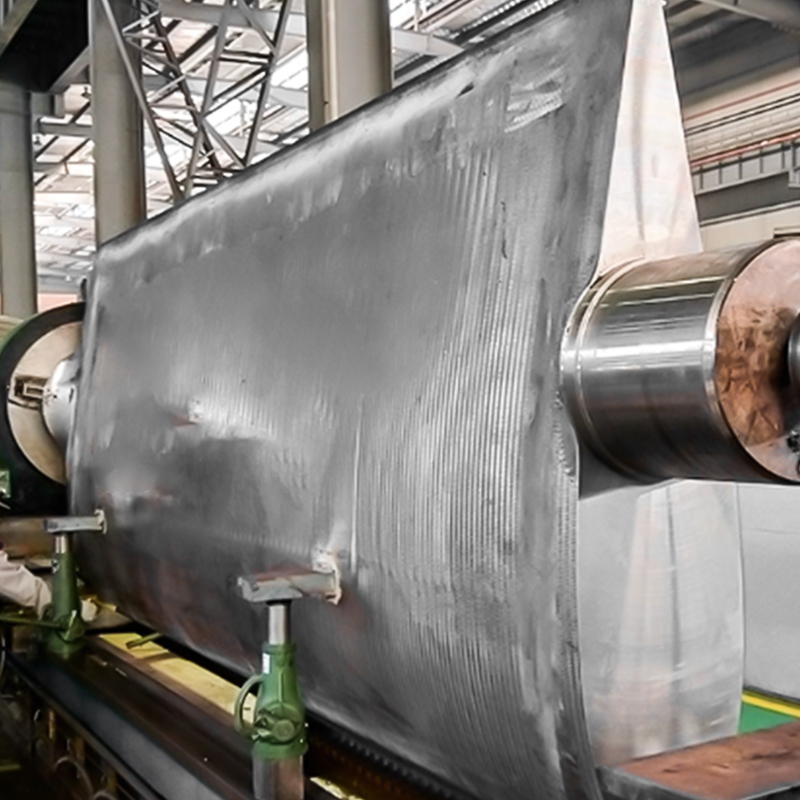

Straightening Roll

Premium materials are selected and treated with special processes, endowing the components with high hardness, excellent wear resistance and impact resistance, as well as a long service life. For example, the nickel-chromium alloy straightening rolls produced via centrifugal casting feature uniform hardness both inside and out, with a slow wear rate—2 to 3 times that of traditional forged steel rolls.

These rolls are suitable for both cold and hot straightening processes, capable of handling various section steels (such as angle steel and channel steel) and reinforcing steel bars. Precision grinding is performed using a hyperbolic grinding machine, ensuring an accurate roll profile. This not only guarantees straightening precision but also significantly improves steel product quality while reducing overall costs.

English

English