Blowout Preventer

1. Applications

They are widely used in conventional onshore oil and gas drilling operations. Whether during the drilling of exploration wells or production wells, when high-pressure oil and gas formations are encountered and downhole pressure may rise suddenly, BOPs can shut off the wellhead in a timely manner to prevent uncontrolled ejection of formation fluids to the surface. For example, in large-scale development drilling operations in oilfields, BOPs are indispensable equipment for ensuring drilling safety.

2. Pressure Control Capability

BOPs possess excellent pressure control performance, enabling them to regulate and control wellhead pressure under different working conditions. During drilling, by controlling the opening and closing of BOPs and the opening degree of choke valves, precise management of downhole pressure can be achieved. This maintains the balance between downhole pressure and formation pressure, ensuring the smooth progress of drilling operations.

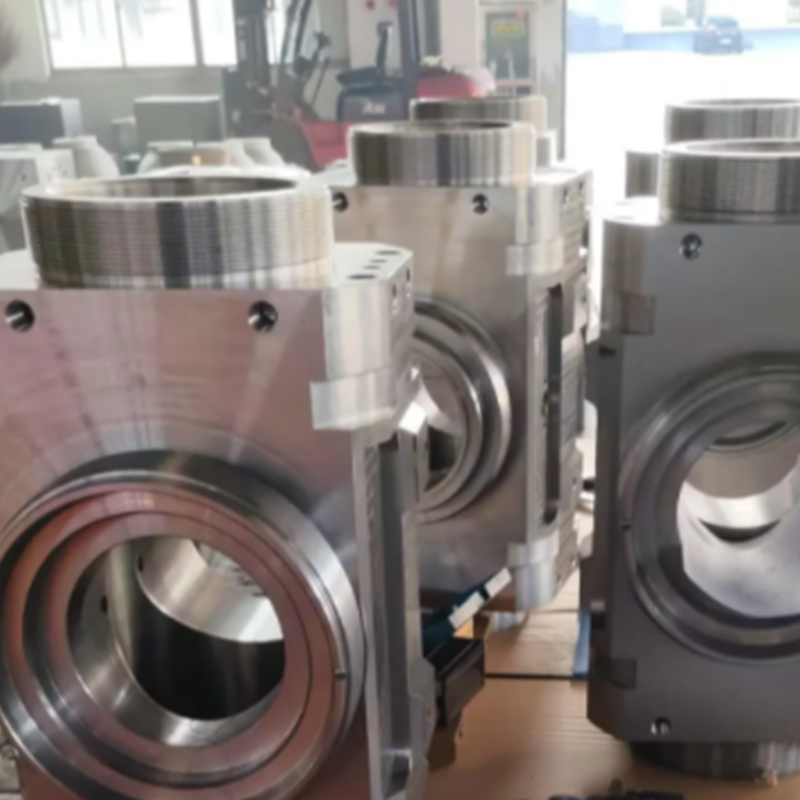

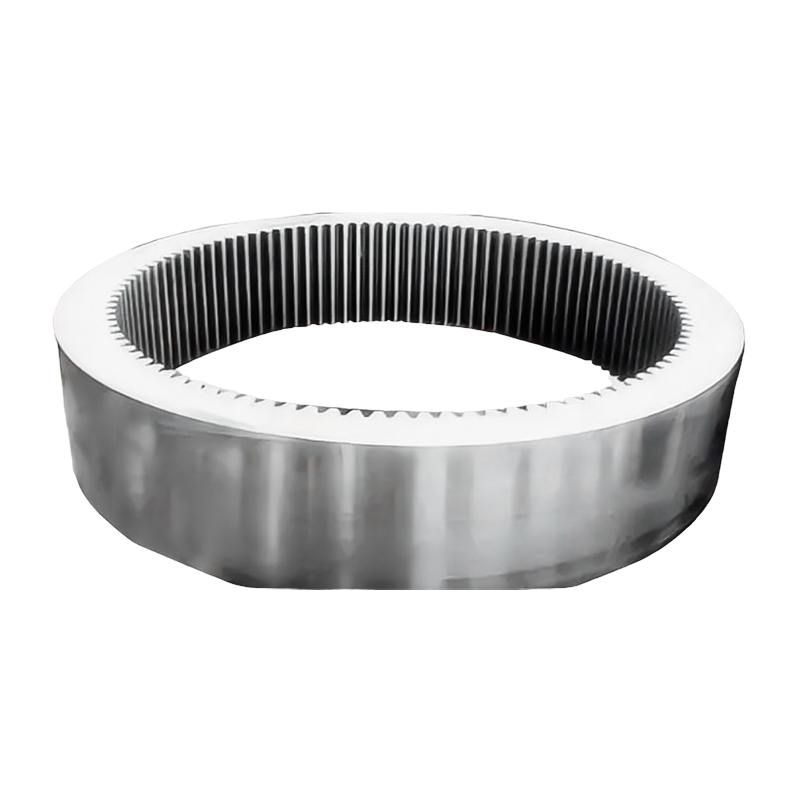

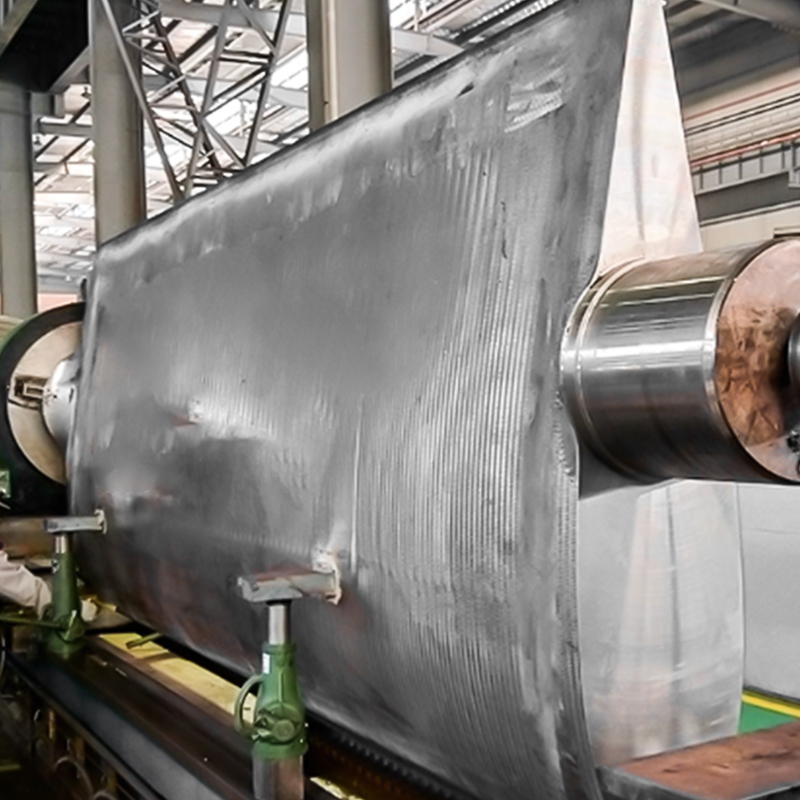

3. High Reliability

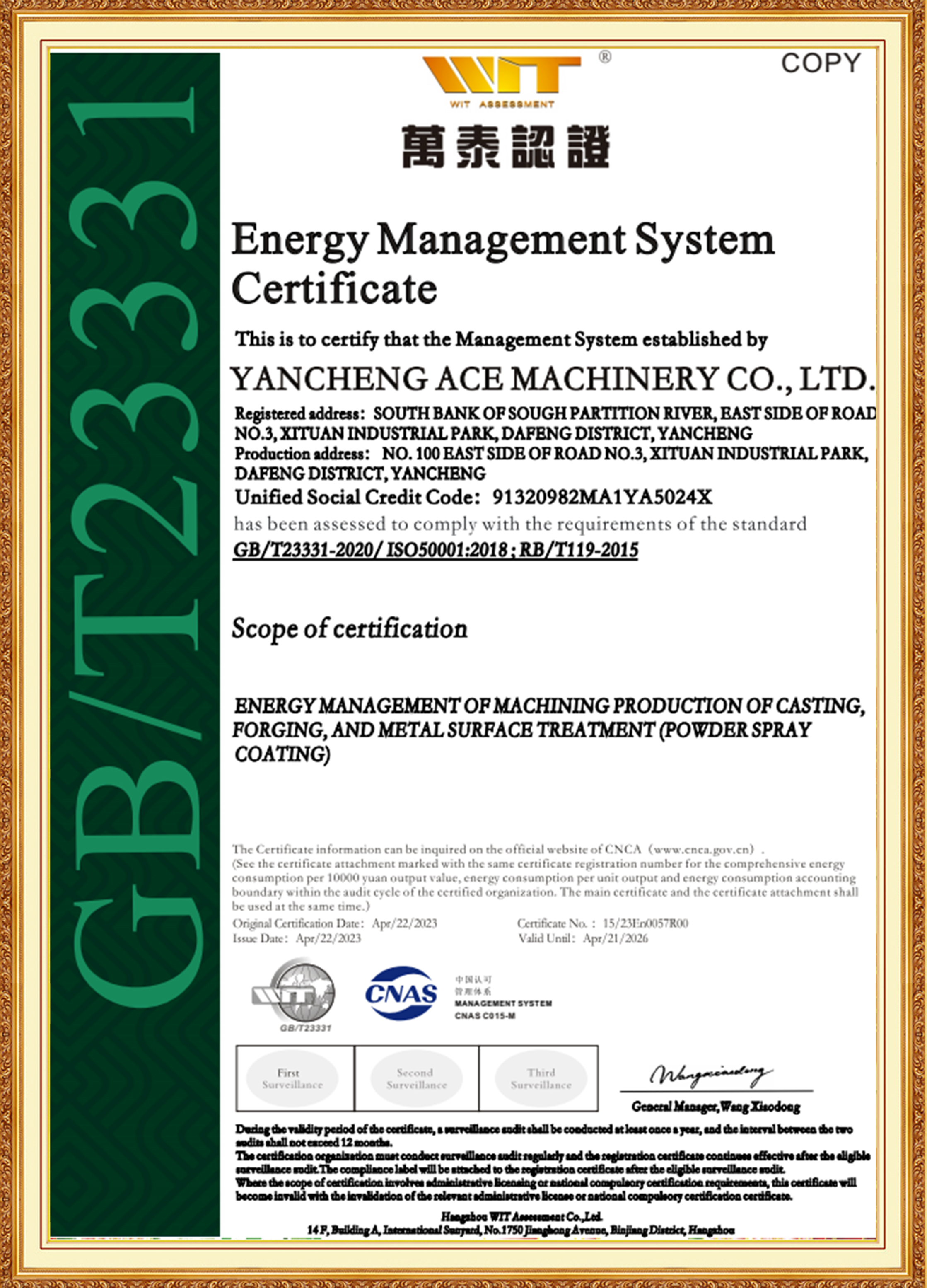

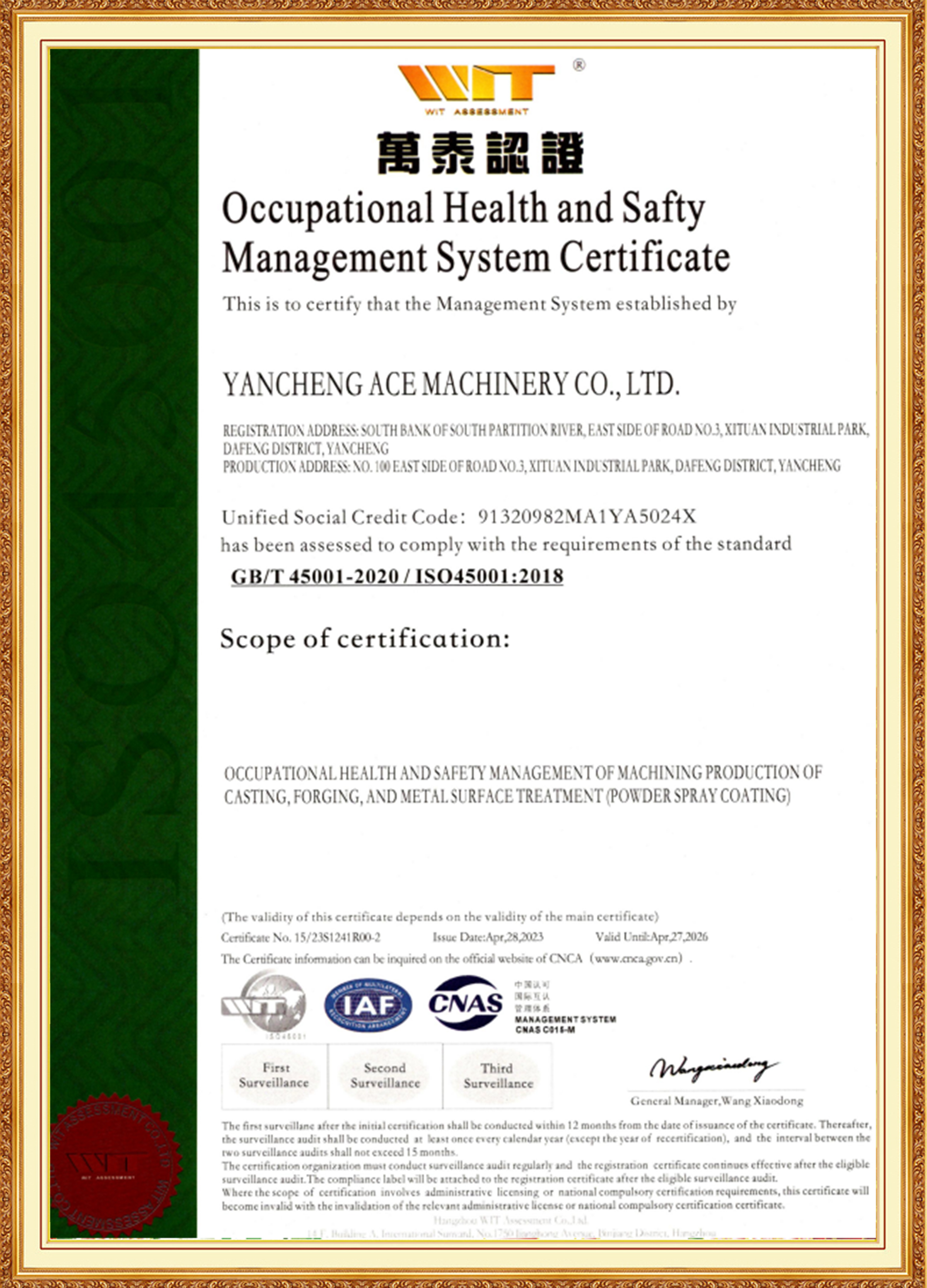

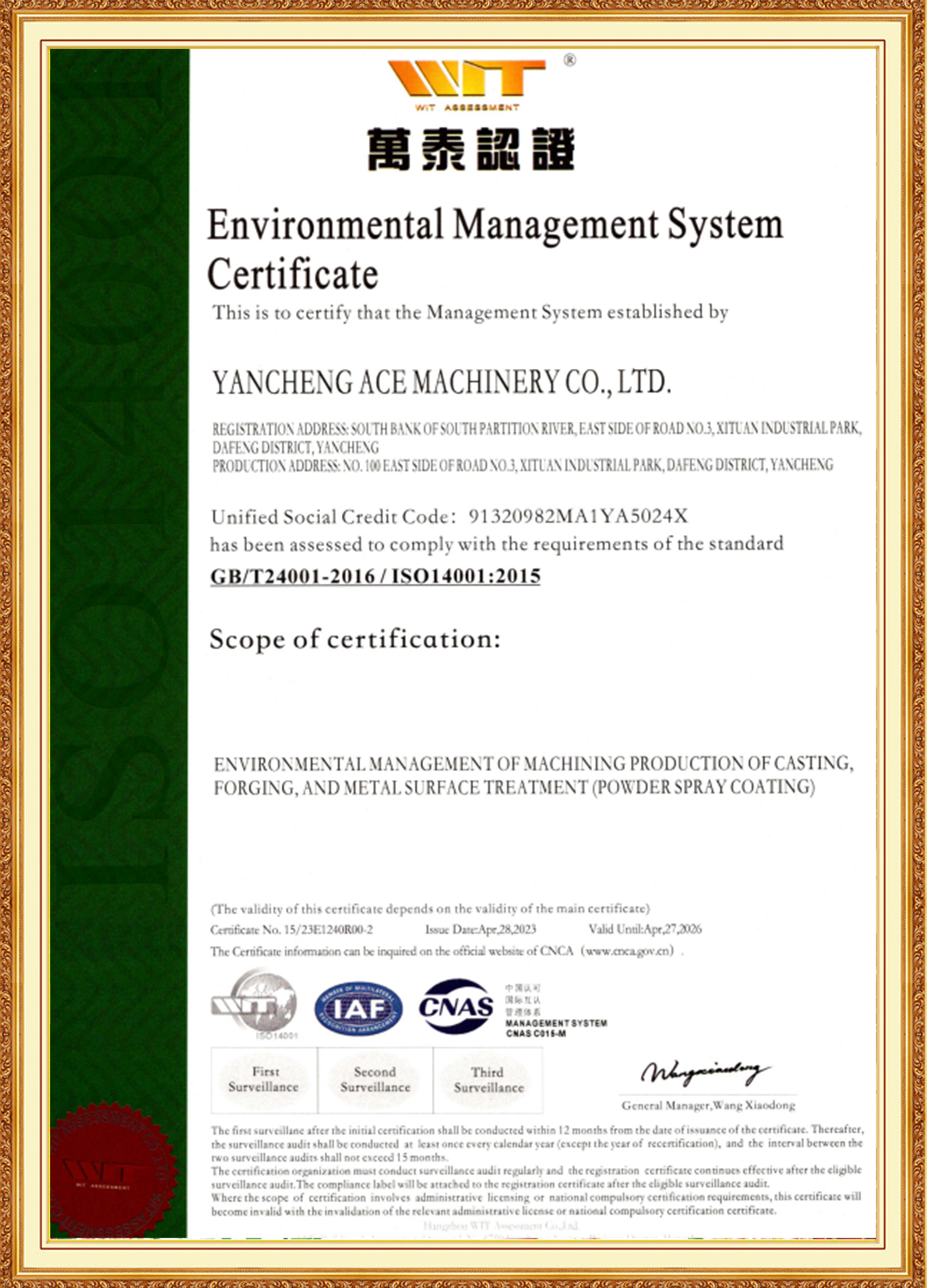

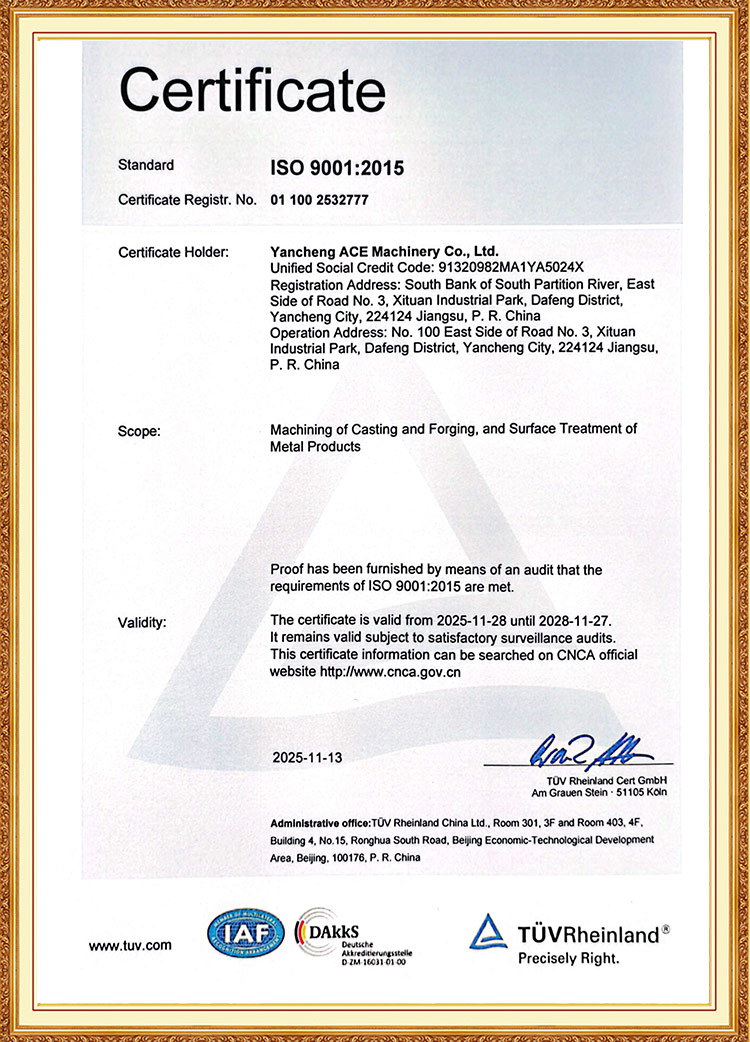

Typically manufactured from high-strength materials, BOPs undergo rigorous quality inspections and performance tests. Their design takes into account various complex working conditions and extreme environments, providing high strength, sealing performance, and corrosion resistance. This allows BOPs to operate stably and reliably in harsh environments, reducing safety risks caused by equipment failures.

English

English