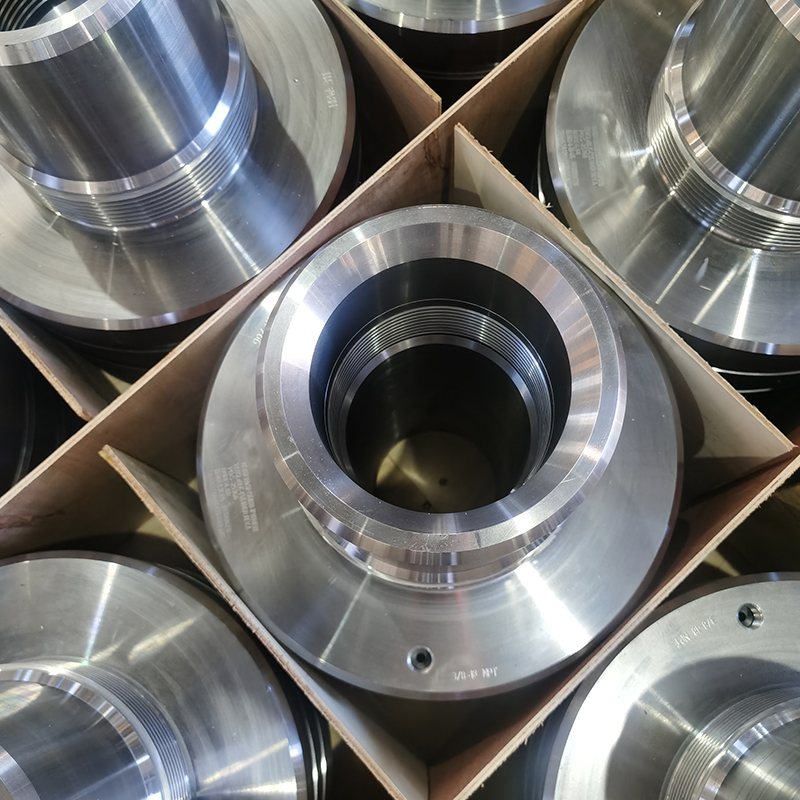

Mandrel Hanger

1. Advantages

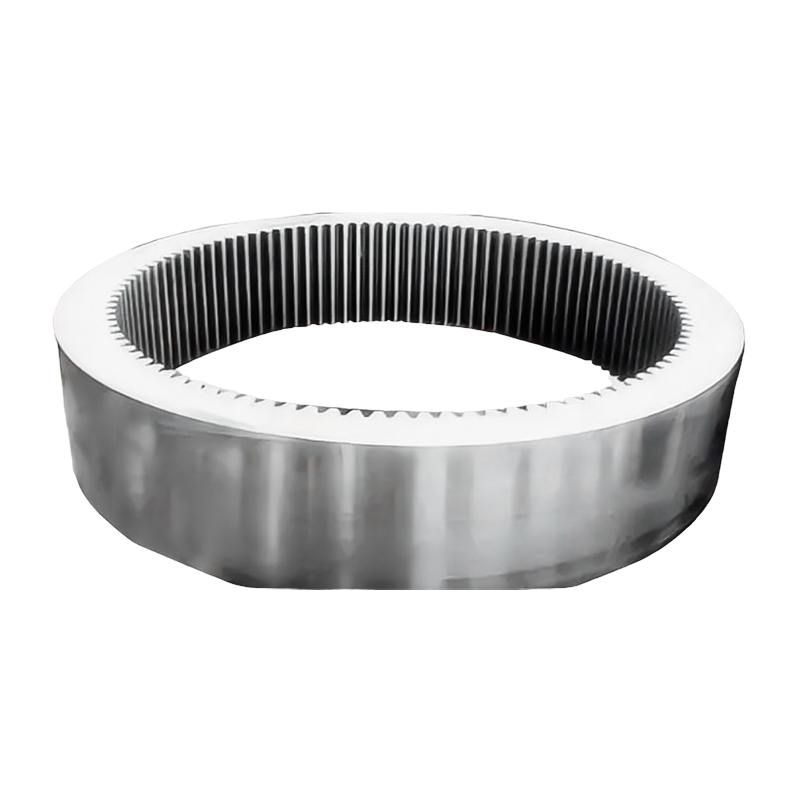

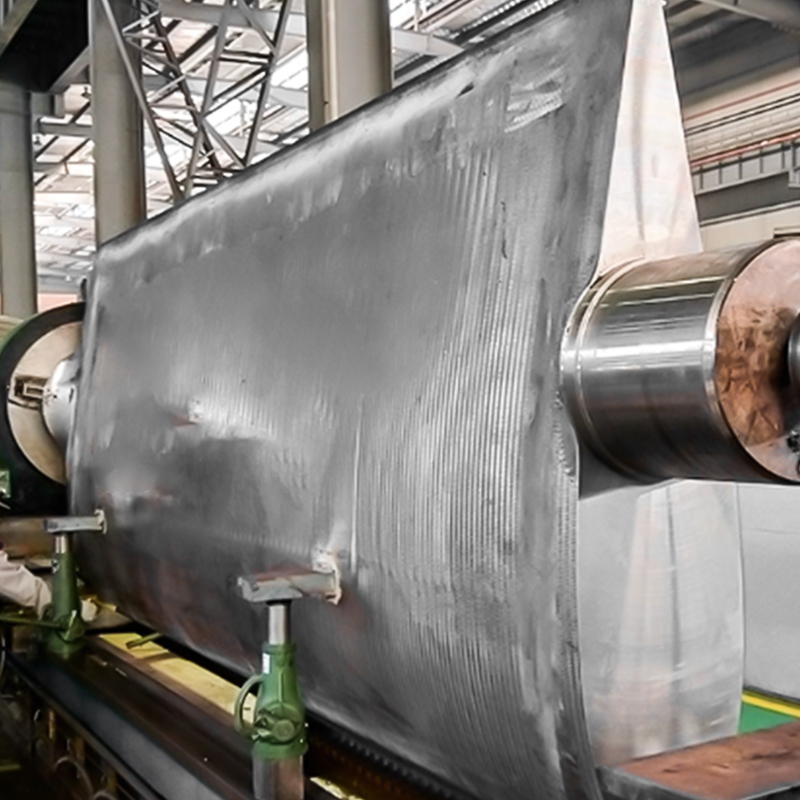

Manufactured from high-strength materials such as premium alloy steel and treated with special heat treatment processes, these components exhibit excellent pressure resistance. They can withstand downhole pressures of up to several tens or even hundreds of megapascals (MPa), maintaining structural stability under high-pressure working conditions to ensure wellhead safety. They are suitable for high-pressure operating environments, including deep-sea and high-pressure gas fields.

2. Selling Points: Reliability Assurance

Leveraging outstanding pressure resistance, sealing performance, and corrosion resistance, they significantly enhance the reliability of wellhead systems.

Reduce unplanned shutdowns and safety accidents caused by component failures, helping oil and gas production enterprises lower operational risks and potential losses.

3. Applications

In conventional onshore oil and gas wells, they are used to suspend production casings and tubing, establishing channels for oil and gas transmission from downhole to the surface while ensuring wellhead sealing. They are widely applied in new well construction, workover operations, and completion operations in oilfields and gasfields.

English

English